3D Printed Drone Parts: What Can You Print & Is It Cost-Effective?

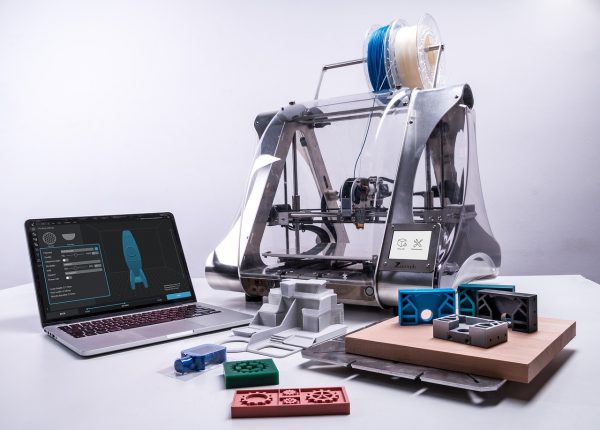

3D printing technology has improved significantly over the past few years, and the price of 3D printers has come way down.

When 3D printers first became available they cost a small fortune. Consumer printers used to cost at least $5,000, which was far too much for the average drone hobbyist.

Now, a good-quality professional 3D printer can be purchased for $2,500 to $4,000 and a consumer 3D printer can be bought for under $500. At that price, 3D printing becomes a cost-effective option for drone enthusiasts.

Almost every part of a drone except the motor, battery, and the electronics can be created using 3D printing.

To create drone parts using 3D printing technology, three things are required:

- A 3D printer (or an outsourced 3D printing service).

- A design model that the 3D printer can use to create the item.

- Rolls of filaments used for the raw materials.

3D Printing Services and 3D Printers

Ultimately, you will likely want to own a 3D printer, especially if you want to make many drone parts or create customized drones from scratch and here’s a list of belt 3D printers.

However, before you jump in and buy a 3D printer, you may want to use outsourced 3D printing services to professionally produce your 3D-printed items. There are many commercial 3D printing services to choose from to get the object made based on the model design you choose.

Craftcloud has an online instant quote system to get a price for a 3D printing job based on the model and the materials you choose. There are plenty of alternatives for commercial 3D printing services.

When you decide the time is right for buying your own 3D printer, you can choose from modestly-priced commercial 3D printers or super low-cost 3D consumer printers. Techradar selected their top choices for 2019 of the best commercial 3D printers and the best values for consumer 3D printers.

Here are the some 3D printers to consider:

Commercial 3D printers under $4,000

- Formlabs Form 2: This professional 3D printer uses a stereolithography process, which provides excellent print quality.

- MakerBot Replicator+: This is a good multi-purpose 3D printer that uses fused deposition modeling (FDM) print technology and prints at a fast speed.

- Ultimaker 2+: This printer also uses FDM technology. There is an extended model also available that accommodates printing taller items.

Consumer 3D printers under $1,500

- LulzBot Mini: Beginner’s appreciate that this printer is easy to use and that the model software is open source. Many developers work with this FDM printer. That makes it easy to find someone to create a model for 3D printing that works with this printer.

- FlashForge Creator Pro: This printer is one step up from the low-cost consumer models. It has the advantage of being bigger to make larger items. It uses a better-quality FDM print technology with a dual extrusion process.

Consumer 3D printers under $300

- XYZprinting da Vinci Mini: This low-cost 3D printer is a great printer for smaller items. Its print area is limited to six cubic inches (six inches width by six inches height by six inches in depth). The print technology it uses is fused filament fabrication (FFF).

- M3D Micro 3D Printer: This consumer printer is a good choice for the novice. It uses FFF printing technology to make small items.

Design Models

There are three ways to get a design model (STL files) that can be used by a 3D printer to produce the items that you want created. They are 1) Download a model design. Most models are open source code and free to download and use. Some, have a modest cost.; 2) Hire a designer to create a 3D model for you according to your specifications, and; 3) Create a 3D model of your own design.

Sources for Downloadable Design Models

Model designs are available as kits to make all the plastic parts needed for a drone. Other designs are available for individual parts and things that can be used to make custom modifications of popular drones.

Here are some interesting kits that are fun to build:

- Drone Quadcopter: This design is similar to the popular DJI Inspire One.

- Spherical Drone: This advanced icosahedron-shaped design is crash resistant.

- Micro Quad: This micro drone fits nicely in the palm of your hand and can be built for under $50.

Some of the replacement parts and accessories that people like to 3D print include propellers (rotors) and guards, frames, landing gear, mounts for cameras, antennas, carrying cases, and casings/covers for batteries or remote controllers.

Here are some sources for models that can be used to make parts:

- Multi-Rotors: This a place to check for rotor designs that are the most commonly replaced parts.

- 3D Printing Drone Parts: This is a forum for do-it-yourself (DIY) drone builders to discuss the hobby and get advice from others.

- Thingiverse: Search this massive database for the design model you need.

How to Hire a Model Designer

All3dp gives excellent tips on how to hire a 3D designer. Expect to pay between $30 to $70 per hour for a skilled designer’s work.

Here are some resources to find a 3D designer for hire:

It is not cheap to hire a designer. If you have a good combination of computer skills and a creative/engineering flair, you may want to become a 3D designer yourself.

Learning How Make 3D Models

To make STL files used for 3D printing you will want to learn computer-aided-design (CAD). There are online courses and in-person schools. There are also self-study resources for those who want to pursue learning on their own.

3D Printing Materials

The materials needed for 3D printing drone parts are called filaments. These come on rolls that look like spindles of thick fishing line.

The plastics/materials used for drone parts include PET/PETG, TPU/TPE, PLA, ABS, Nylon, and carbon fiber. To learn more about the filament choices and the materials specifications read the 3D Printer Filament Guide for 2019 and the 2019 PLA Filament Guide.

Conclusion

Most drone hobbyists who get into 3D printing do so as an extension of what they already love to do. Drone pilots who are into racing are very attracted to learning how to make their own customized parts.

On a purely cost-analysis basis, if the replacement part is available for less than $30 to $50 then it is probably cheaper to buy it than to pay a 3D printing service to make one for you.

However, this incremental cost per part goes down if you own a 3D printer. Then you need only compare the cost of buying a part with the cost of paying for the materials needed to print it, assuming you can download the design model for free.

If the part is very expensive, discontinued, or it is a custom-made part that cannot be purchased then 3D printing is the way to go.