Getting To Grips With Laser Marking Technologies

With the advent of technology, the process of marking has not only become easy but rapid too. This is why it doesn’t matter how many products you have lined up, they will be marked by the end of the day as per the capacity of your machine.

Moreover, the invention of the Portable Marking Machine, Dot Peen Marking Machine, CO2 Laser Marking Machine, Mini Laser Engraver Machine, etc have further made things simpler by adding precision.

Now although, there are many technologies that have contributed to the marking, the one that has left the mark is laser marking technology.

Want to know how?

Let us dig deeper to know how Laser Marking Technology enhances your work.

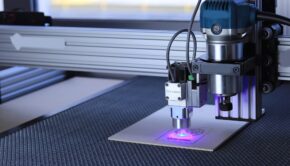

Laser Marking

It is one of the best ways of marking/engraving. This all takes place due to the interaction of electromagnetic radiation with the material. If we talk about the mechanism of material removal, it includes different stages. It all begins from melting followed by vaporization and then chemical degradation.

If we go into more detail, the high energy density of a laser beam is made to focus on the work-piece surface. During this, the thermal energy is absorbed by the work-piece. As a result, the work volume is heated and transformed into a molten, vaporized, and finally into a chemically changed material. This material is made to be removed easily by the flow of a high-pressure assist jet.

Although it comes with many other features, the usage of limited consumables as compared to labeling or printing is the one that stands out in its favor. Moreover, laser marking machines are best known for their safety, minimum maintenance, and easy-to-operate capabilities. This is the reason why the demand for Laser Marking Solutions is pretty high in the market.

But the thing that makes laser marking unique is its advantages over other technologies. It is known for its mark clarity, permeance, speed, and so on. Within a short span of time laser utilization has become one of the most efficient, modern, and reliable techniques of marking.

To get a better idea of same, let us discuss this in detail

- Traceability: It offers you the ability to mark directly and permanently on the part. You are going to get an added advantage over other marking methods as laser offers you the option of marking at the beginning of the production line.

It doesn’t matter if marking is performed before treatments like shot blasting or e-coating, it keeps high-quality marks throughout the entire life of a part. You need not worry about preserving the quality of data matrix, barcodes, or alphanumeric serial numbers.

- No consumables: The marking operation is simplified due to the absence of consumables. It also promotes health and safety in the workplace as chemicals and ink are completely replaced. Most of all, it is cost-effective as operation cost is less as compared to other techniques.

- Rare Maintenance: The good thing about laser marking machines and systems are, they don’t have moving parts. This means the possibility of the breakage of components is rare. They also produce less waste as compared to other machines that were in use earlier.

Current technology

If we talk about the current technology, the laser systems are built to last for a longer period of time. CO2 laser provides approximately 40,000 marking hours. On the other hand, fiber lasers have the capacity of 100,000 marking hours.

- Fiber lasers are best known for marking metals. They are considered to be solid-state lasers. When it comes to the technology involved, they have a laser source in the form of optical fiber. The metal used for the same is one of the rarest metals like ytterbium. The laser light produced by such metal is on a wavelength of approximately 1 micrometer (1064nm).

- Gas state laser systems are best known for marking organic materials. The most common gas-state laser is the CO2 laser. The light wavelength for this kind of laser ranges from 9 micrometers to 10.2 micrometers (9,000-12,000nm). They are not suitable for metals as metals react poorly with these wavelengths.

Moreover, it doesn’t matter whether you are going to use laser marking technology in packaging, pharmaceuticals, food & beverages, or in any other sector, you are going to get quality and precision in your operation. It carries its applications in printed circuit boards, metals, medical devices, etc. Lasers are well known for Industrial Engraving and Marking Applications all around the world.

Conclusion: If you are really looking for Industrial Engraving and Marking Systems and that too with the state-of-the-art-technology, laser marking technology is the one you can go with. It is one of the modern technologies that not only reduce efforts and time but also carries precision. Moreover, the cost of operation is also lesser as compared to other machines.

Author Bio

HeatSign is one of the professional dot peen and laser marking machine companies. With over 10 years of experience in the industry and international certifications, it offers you cost-effective and quality marking solutions.