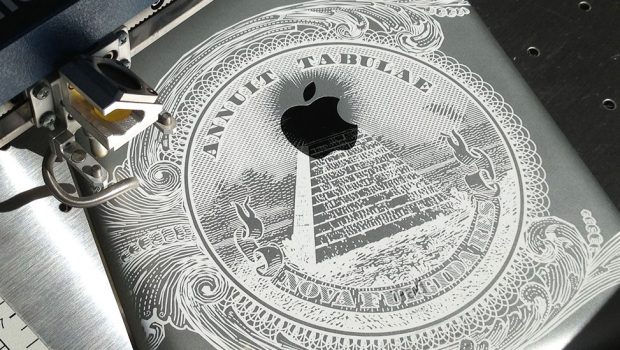

Best Practices For Laser Engraving On Stainless Steel

Laser engravers are powerful devices that can be used to make markings on any chosen material like iron and stainless steel. Applications in stainless steel usually include making medical equipment and travel cups that are in a high demand these days.

If you’re looking to use the laser engraver to make markings on stainless steel, than below are some best practices that you can follow to make sure the process is done effectively.

Calibrate The Machine For Good Results

The reason why laser engraving machines are preferred over their counterparts is that they have the ability to make deeper cuts and more details to help the product bear extreme pressure and stress without losing its engravings.

If you’re also looking for deeper cuts than you can adjust the machine to increase its power and decrease its speed to achieve the desired depth if engraving on your product. Using the machine this way will definitely slow down the machine a bit, buy it’d help you achieve the desired results too.

Use Multiple Passes

One of the biggest mistakes that most of the novice laser engraving machine operators make is that they calibrate the machine to complete the engraving in a single pass. If the laser stayed at a point for way too long, it can ruin the final product by heating things up.

That is why you should always use multiple passes over the same design to achieve the desired depth. However, as mentioned in the first step, you can make the machine a bit slower to complete the process early.

Learn The Designing Requirements

When it comes to managing and running a sophisticated process like laser engraving, you have to learn all the necessary designing skills to achieve good results. For example, having the knowledge of vector files is a must if you want to input the files yourself into the machine and engrave on stainless steel.

For the moment you start designing the vector file of the product, keep the end in your mind to avoid any inconvenience later on.

Test The Machine First

Whether you’re looking to make one customized product, or mass produce a product for business purposes, make sure you test the machine first by making the design on an identical, inexpensive product to save the actual product from wasting away. This way, you’ll be able to access the needs of your machine and its designing features even before starting the actual process, so, you’ll be in a position to calibrate the machine beforehand.

Take Precautionary Steps

Taking precautionary steps can help you prevent the harmful effects of any fumes and microscopic particles made during the laser engraving process. Laser engraving machines are electronic devices, and precautionary steps including wearing a mask, keeping away from the wires and doing the process in the supervision of an expert must be followed.

These were some best practices that you can adopt in stainless steel laser engraving, you can also visit this link (www.heatsign.com/all-you-need-to-know-about-laser-engraving-machine-for-metal-cups/) to read more about making different stainless steel products.