Using Signals from Data Loggers, New Supply Chain Technology Is Improving Profits

From the outside, it may look as though the world of supply chains hasn’t changed much over the years. Logistics companies carry materials from suppliers in one location to buyers in another via air, sea and road routes. Eventually, products reach an end consumer. Simple, right? Well actually, in the complex world of IoT-enhanced logistics and supply chain analytics, much has changed.

Indeed, products do travel in much the same manner that they did 20, 30, or even 100 years ago, but the complexities associated with that travel have increased exponentially. In the hectic modern era, it is no longer as simple as making sure the package arrives.

Routes must be optimized and followed for efficiency, industry-specific regulators’ requirements must be met, and a thorough log that demonstrates exactly where each shipment was at any given moment, and under what conditions, must be made available to assure transparency and trustworthy quality control.

Things get increasingly complex when dealing with products that are fragile in one way or another. Whether they are temperature sensitive, need to stay upright or in the dark, vulnerable to humidity or jostling, many vendors and buyers alike need the peace of mind that data loggers bring to the table.

Capturing the data that matters for logistics

If you’re shipping steel beams, that’s one thing. But if the goods being shipped are vulnerable to environmental conditions, having the ability to point to data reports on several relevant parameters is immeasurably useful when identifying issues that arise during their journey.

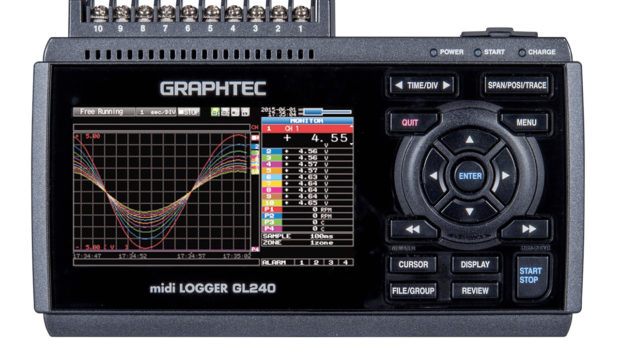

Simply put, data loggers produce reports via sensors attached to consignments on a whole plethora of information, sending these signals back to a central system. This data can be the temperature during transit, the level of movement during transportation (think shocks and bumps), the humidity of the air within the shipping container, the level of tilt experienced by the consignment, and whether the consignment is exposed to sunlight.

Part of the improvements made in the logistics industry, and in particular with cold chain monitoring, is down to the connectivity available for these data loggers to make information available to those who need it in real-time. Being able to see exactly where a consignment is, the temperature it is currently being kept at, along with and fluctuations along the route, can allow a brand, manufacturer, shipping partner or buyer to plan ahead with far more accuracy than they would have done in previous, more rudimentary logistical times.

It also keeps everyone on the same page when it comes to meeting required standards and avoiding disputes when shipping companies fail to live up to their service level agreements. When there’s cold, hard, data from usb temperature data logger to prove that a consignment wasn’t treated with the care it should have been treated with, then there are no surprises when sensitive engineering equipment arrives mis-calibrated, food arrives past its expiration date or chemical samples arrive having lost their potency.

This level of transparency, in turn, puts logistics companies in the spotlight to prioritize the care they provide for their customers’ consignments, which, as the logistics industry continues to grow, is a good thing for everyone involved.

It isn’t just about proving what happened during the transporting phase either. Being able to see exactly where a consignment happens to be, allows intended recipients to react quickly to delays. Having a tilt or excessive movement detector relay information about a problematic journey can also allow you to plan a different route in the future, or even use a different logistics company entirely.

Automatic alerts mean peace of mind

Many new cold chain monitoring services can be configured to send the end user automatic alerts when there is an issue within a prescribed area of concern.

This means that the customer doesn’t have to sit and keep an eye on things actively but rather can move on to other aspects of their work life. If they wish to review a report at the end of the journey, or if they feel the need to check up on the latest with a given consignment, they can do so at any time, but modern data loggers have provided us with a service that keeps an “all-seeing eye” over our components or products on our behalf.

To reiterate, data loggers can save a business money in a variety of ways. They can provide data that allows you to plan for more efficient transportation types, routes and service providers. They give recipients peace of mind, allowing them to get on with other tasks, and not waste time worrying about a shipment, or calling up the logistics firms for updates on condition and location. They collect information in real time about issues that arise, letting you plan a course of action before the shipment even arrives at its destination.

All of these facets can allow a company to save a considerable amount of money in the long run, especially when you take into account that the initial investment in logger device hardware becomes more affordable over time.

Today, demand for reliable logistics services is on a strong upward trajectory. Armed with contemporary data loggers, stakeholders throughout the supply chain are in better position to keep their components and products safe, their transportation efficient, and their backs covered in the case that something does go awry.