Diffractive Random Dot Generator – 3D imaging & beyond

3D Imaging

With the rise of modern gadgets and technological advancements, two-dimensional imaging methods seem increasingly limiting in how we perceive, and image, the world around us. Since we experience the world around us in 3-dimensions (3D), there is a clear need to develop technologies that can image in 3D. This has been achieved in the past by imaging the same scene from two different angles in a process similar to how human vision functions.

However, advanced 3D imaging methods that are simpler to implement, such as structured light vision, are growing in popularity as an alternative way to sense depth . In this technique, structured light with a known pattern is projected onto a scene and its reflections are captured using a sensor. An image processing algorithm then analyses the deformations in the collected reflected patterns and reconstructs the 3D topography of the scene.

Random Dot Projectors – DOE

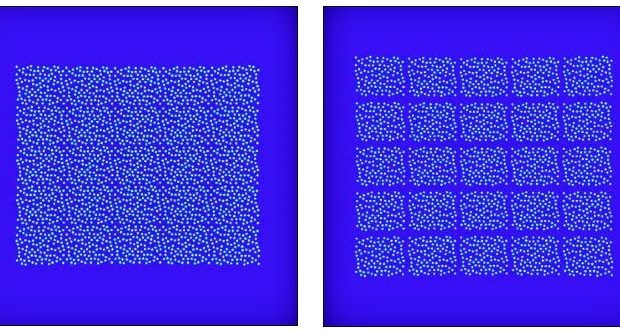

Recently, there is a strong preference to use random dot pattern projection as the structured light pattern for 3D sensing. Such patterns allow for unique positional encoding and reconstruction by the image processing algorithm. To put it in simple terms, in a typical random dot generator light from a laser source is split into the desired number of random or pseudo random dots, typically into several thousand dots, using a diffractive optical element (DOE). This is known as Diffractive random dot generator.

To scale up the imaging range, often the light from a random array of laser emitters (a VCSEL array) is collimated (usually with a DOE collimator) to form a “tile” containing multiple dots, then duplicated using a DOE beam splitter into several orders ,or tiles. The centers of these tiles must be carefully positioned so that they are perfectly stitched together, generating a random dot pattern over a large imaging range, thereby imaging a large field of view. Each tile is a replication of the original random array of dots from the lasers. In this case, it is crucial to ensure that the individual tiles are precisely stitched together. Any deviation in the DOE splitter or collimator design might lead to an incorrect dot pattern with overlaps or gaps.

Fortunately, there are DOE designers & producers who can deliver random dot projectors with excellent specifications that meet specific user requirements. Due to their design flexibility, DOEs can achieve optical functions that otherwise require complicated optical systems. Such DOE based random dot projectors have several unique advantages, as the microstructures in the DOE can be tailored to provide any intensity or pattern for a specific application allowing for customization. Crucially, DOEs are much thinner and lighter, making them a go-to solution for compact imaging systems.

Such DOE based random dot projectors are set to revolutionize 3D imaging capabilities through better performance and miniaturization. They are already found in many day-to-day applications such as smart phone facial recognition, retinal scanning, fingerprint scanning, barcode reader, etc.

They are also increasingly finding more applications in next generation technology such as access control, smart surveillance, VR/AR glasses, robotic computer vision, automotive Lidar and 3D area mapping, to name a few.