Important things to know about Pancake Slip Ring

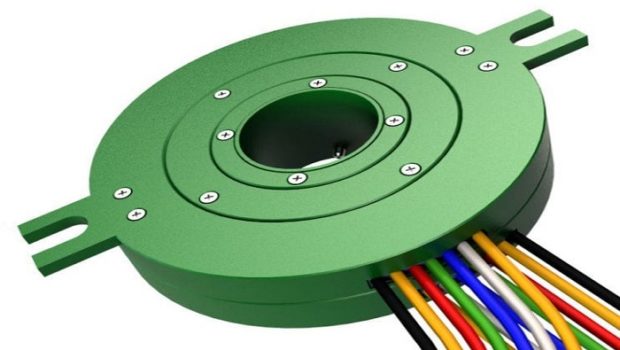

First Look

Pancake sort connections area unit utilized in applications. Cake slip rings area unit used e.g. in medical, measure, test, print and textile trade. Combined makes conjointly massive cake slip rings for declaimers utilized in bulk material handling trade. Those cake slip rings have generally through bore between 500mm to 1000mm. cake slip rings that area unit product of many items could have even larger diameters. Those slip rings area unit referred to as Split cake slip rings.

Information

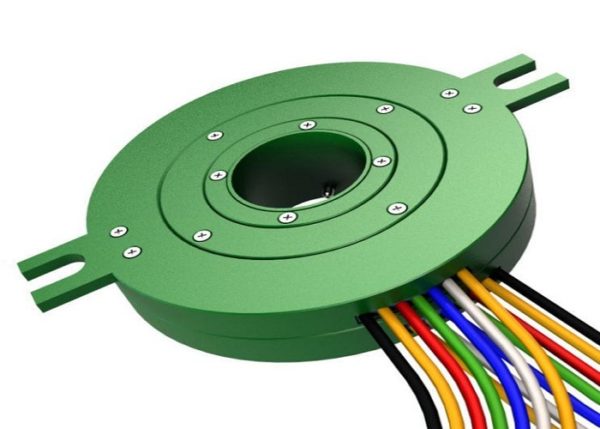

Pancake slip ring is meant for a restricted height scenario, that doesn’t have any limitation in OD. This series connection has options of minimum height/thickness, large OD, it’s sort of a plate, so it conjointly referred to as plate connection, victimization valuable contacts, and it’s the table.

- Min thickness will be 18mm

- Cake connection victimization vacuum assistant organic compound infusion method.

- Victimization valuable contacts that is stable, low contact resistance and high performance.

Pancake slip rings square measure designed for space-critical applications relating to height dimensions. Because the flat form is comparable to a platter, they’ve additionally named flat slip rings and platter slip rings. The battercake slip rings with housing square measure the same as the through-bore slip rings with the special specialize in minimum height. The client will choose between radial cable output with minimum height and axial cable output.

Looking on the need of the client we provide 2 totally different qualities of through-bore slip rings: common quality and industrial quality. Looking on the standard designated, the operating life, max. Rotation speed and get in touch with materials vary. Oil, gas, mining, and a few military applications need explosion proof on devices like slip rings. The wants are divided into zones, product teams, explosion teams, and temperature categories. Most slip rings operate at many hundred revolutions per minute. Some applications, like high-speed rotor testing, need rotation speed as high as a 100,000 rpm.

LPK series for cake Slip Rings

LPK series may be a cluster of cake slip rings factory-made by JINPAT with the thickness as little as 6mm. they’re designed completely for the rotation system within which putting in the house is restricted tall within the vertical direction. Each the copper ring and brush contact surround a central hole, that saves house heaps. LPK series connection is split into a pair of kinds: separate cake connection LPSK and LPK complete cake connection.

Features on it

- High rotating speed and unfailing contact.

- Light figure or high model.

- Extremely low physical noise.

- Transmitting power and signal in an exceedingly 360-degree rotation.

- No interference or affiliation drop.

In all this stuff there is mercury slip rings also available on it.

How to opt for Slip Ring

There is no natural distinction among SNK series battercake slip rings, through the outlet connector and capsule connecter. All of them may be accustomed to conduct electricity, through hydraulic and vacuum or transmit varied signals for the devices wherever would like 360° rotating. The length of the through-hole connector and capsule connector may be prolonged long ways while not limitation. However, battercake connector transmits a lot of current and signal channels through infinite cross enlargement on connector diameter (ring number). The accessible installation area of the apparatus shall take care after you square measure selecting the model.

If the space of rotating elements is restricted, the SNK series battercake connector may be thought about. With years of researching and developing and producing expertise, Sending presently incorporates a mature technology. The thickness of the connector here even will reach to 6mm, which may meet most of the exactness styles of instrumentation that have a compact area. If you’ll be able to not notice appropriate models here, please contact the sales personnel of Slip ring to form customization. All the parameters together with whole size, height (thickness), OD, materials, IP grade, etc. of slip rings may be made-to-order.

- Height (thickness): 6-30mm (Kinds of thickness may be customized);

- Whole size: while not a hole (solid) ~120mm, another whole size may be customized;

- Rings: 2~36(more Rings may be customized; a lot of rings, a lot of current channels or signals);

- A lot of specification: will customize a lot of parameters; will style through whole connecter with any specs.

Making Method

With the event of communication technology boost the liability between the devices and instrumentation. In some cases, the connected rotation between connected devices in the meantime transmits the present and signal through a cable wire. Because the cable wire is simple to bust if use directly uses the cable wire, thus CENO develops a form of shell hot cake connector replace the cable to transmit current and signal for the connected 2 devices.

Normal hot cake slip ring adopts convexo-convex purpose structure. T hanks to shell elastic are weaker, have an effect on the 2 items of PCB poor contact throughout contact friction. As CENO resolved this sort of issue, currently let’s introduce the structure of hot cake of CENO.

CENO electrical connect the 2 pieces of PCB; keep the 2 aspects rotating around one axis to transmit the signal and current. One aspect PCB( first) is coming up with the receptacle with the operate of rotating, the opposite aspect PCB aspect weld the connective shell with the stator coil operate, the fastening purpose consistent with the receptacle within the initial aspect PCB. These 2 aspects PCB connect along to create certain the connector continuous rotating and transmittal current and signal while not the cables are twisted.

Final Views

Pancake connector is specially designed for rotating systems that are restricted tall. It’s a special conductive connector. There’s a huge array of product on the market to deal with specific technical challenges. Most are created to orders and many are commonplace from off the shelf. Various makers with cantered technologies and targeted industries are often found in most industrial countries.