Trends to Look for in the Metal Fabrication Industry

The metal fabrication industry has long been the backbone of the global manufacturing and engineering sectors. From construction, electronics, aerospace, automotive, manufacturing, energy & power to defense and others, there is an enormous end-user market for the metal fabrication industry. Although the industry took a nosedive at the turn of the century, there has been a positive outlook over the last few years.

Businesses operating in the metal fabrication industry are adopting new trends and business strategies, repositioning their markets and implementing various new developments to spur growth in the market. Here are a few key trends that are changing how businesses operate in the metal fabrication industry.

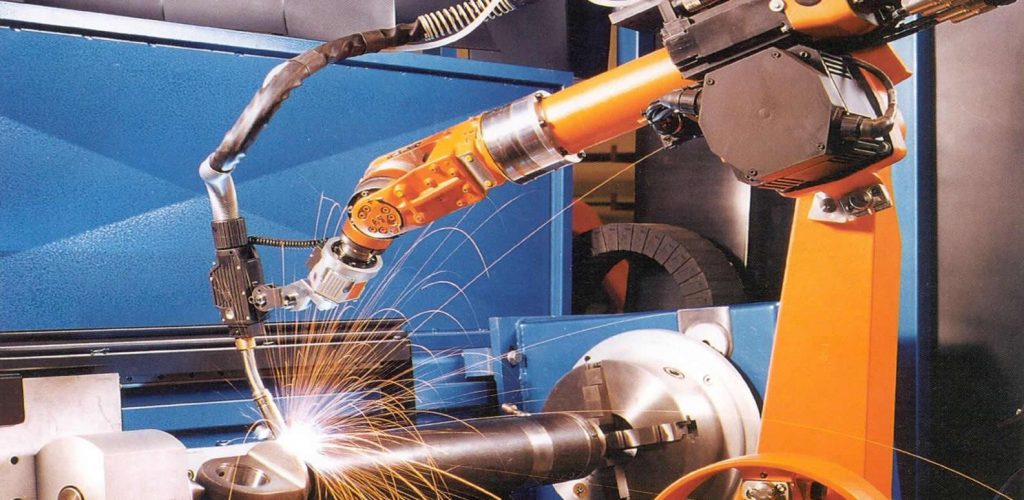

Automation

The rise of automation has no doubt changed the nature of many industries including metal fabrication. Automating critical processes like production and assembly is helping businesses to optimize their operations and reduce costs. As robotics technology continues to improve, automation is one of the trends that businesses in the metal fabrication industry are set to embrace in the coming years.

Additive Manufacturing

Also known as 3D printing, additive manufacturing is today considered one of the technologies that will shape the future of manufacturing and other industries. More and more metal fabrication businesses are planning to invest in 3D printing technology to create both simple and complex tools and structures. The technology offers the possibility to create and produce complex parts without the design challenges associated with traditional manufacturing processes.

This trend is expected to grow immensely in the coming months and years, especially because the process encourages innovation and makes manufacturing more efficient while reducing wastage.

Reshoring

One continuing trend to look for in the metal fabrication industry is reshoring, also known as manufacturing regionalization. Many businesses are now moving from an ‘offshore’ model to a ‘nearshore or onshore’ model, where manufacturing services are closer to where market demand and innovation take place. Some of the drivers behind the rise of reshoring and manufacturing regionalization include the increase in foreign wages in countries like China, rising transport costs and market volatility risks.

More regional players in the industry are moving their fabrications to the U.S and other favorable environments. As the trend of reshoring continues to grow, companies must boost their capabilities and embrace new technologies to remain relevant in the supply chain.

Emerging Markets

The rise of emerging markets has over the last few years offered the metal fabrication industry lots of new opportunities in various growth sectors leading to rapid globalization. Well-established businesses in the industry are well positioned to deal with new business environments, new local and global markets and also adapt to rapidly changing market conditions.

Emerging markets and renewed growth in domestic manufacturing industries are huge trends that are expected to offer metal fabricators greater opportunities to expand their operations and meet growing demand for their services.

Strategic Enterprise Planning and Management

Most metal fabrication businesses operate different facilities in various locations, both in their domestic and global markets. Managing and tracking operations in different facilities is a huge challenge for component manufacturers and suppliers. One of the key trends changing how metal fabrication business plan and manage their operations and is ERP (Enterprise Resource Planning) solutions.

ERP solutions play a huge role in operational performance planning for metal fabricators. Enterprise mobilization is an important trend that is expected to streamline operations in the manufacturing sector, enable strategic business planning and offer real-time analytical data for business processing.

Investment in Research and Development

More metal fabrication businesses realize the need to invest in research and development so as to keep ahead of the competitive manufacturing market. This new trend is enabling them to develop new technologies and expand their market reach. Many fabricators and manufacturers worldwide are increasing expenditure in research and development to drive growth and are constantly looking for new and emerging opportunities to grow and compete in the market.

Overall Positive Outlook

Based on these new trends, it’s clear that the metal fabrication industry has a positive outlook in the coming decade. Although the industry is shifting and having an impact in certain markets like the U.S, Europe and China, current trends show that demand will continue to rise. Manufacturers and clients in the numerous industries rely on industry recognized companies like Metal Supply for fabrication services and anticipate a stable and profitable future over the next few years.

Author Bio:

Carolyn Clarke is a freelance writer and a manufacturing and supply chain operations expert who helps businesses understand new manufacturing technologies and trends in the metal fabrication industry. She works with businesses based in Los Angeles, CA and the surroundings areas. She takes pride in helping organizations reassess their processes, technology and innovation strategies to improve their operations.

Pingback: Trends to Look for in the Metal Fabrication Ind...