100+ Suns Hitting A Rooftop Near You

Solar technologies are more than an innovation—they’ve become the epitome of alternative energy driving the green movement. Something about harvesting sunrays resonate with people, to the extent that an overwhelming slice of grassroot efforts and petitions are pro-solar; cut taxes; ditch coal; expand options; and the list goes on. The government responds well enough, with billions of funding for clean energy research and incentive-driven solar initiatives like feed-in tariff (FiT) programs and free panels.

With unprecedented grand-scale support, solar technology should have skyrocketed a long time ago, no roofs left behind. But at most 50% of houses in a typical neighborhood would have solar panels installed, making us still very much nuclear-reliant. Much of solar development’s incompetence is due to the fact that conventional energy harvesting systems are simply not meeting efficiency standards; flat panels are capable of converting at most 35% of photons into effective power, with the actual number being somewhere around 15%. As a response to low output, a bright idea rose to boost efficiency and it comes with a focus―concentrated solar power (CSP), aka concentrated photovoltaic (CPV).

Looking Back: CSP Technology

CSP technology consists of a non-obstructive concentrating optic mounted on top of a multi-junction PV cell, roofed by short focal-length fresnel lens.

This design enables scattered sunbeams to become more focused through a reflection and refraction process before hitting a tiny multi-junction PV cell occupying a few square millimeters in the magnitude of hundreds of suns. The cell then convert 40-50% of received photons into electricity while dissipating the rest off as heat. To uphold this efficiency, several things need to be addressed during implementation:

High precision tracking system

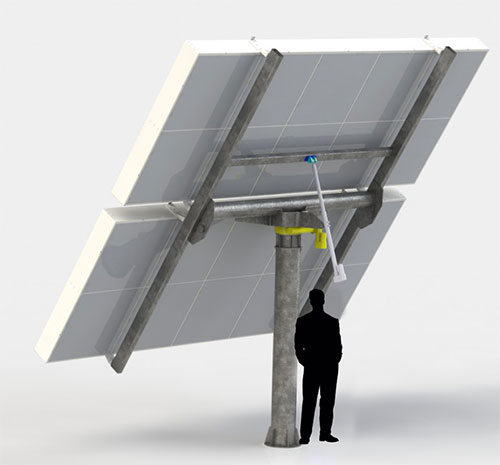

Because CSP’s PV cells are so small and limiting reflection coefficients, a precise mechanism for directing sunlight to maintain its entry angle at 90 degrees is required. This gives rise to motorized systems that accompany the CPV modules to track and self-adjust automatically with incremental movements of the sun.

Passive cooling system

PV cells work better under cooler temperatures which means modules require effective cooling. To this end, CSP industries have leveraged heat-pipe cooling or water cooling systems to prevent solar cells from overheating.

Robust module

Both optics and multi-junction cells need protection against harsh weather conditions such as humidity, wind, dust, rain, etc. Robust modules can ensure optic-cell alignment against outside conditions, maintaining optimal functionality. CPV industries have adopted varying designs:

Pyron Solar’s HE module:

ArzonSolar’s Universal module:

IBM’s Sunflower module

Notice their bulkiness? Robust to be fair, but problematic as well. Fabrication costs aside (funding required no doubt), their large size narrows their market scope to open-field utility suppliers. And if not enough big companies bite, CPV industries are out of luck. Increasing market share undoubtedly requires re-aiming their platform from desserts to rooftops. Why? In the words of Shayle Kann, VP of Greentech Media research, “residential solar is the fastest-growing and potentially the most transformative sector of the solar market.”

If CPV sectors want a share of the “transformational” pie, industries need to appeal to households. Until recently, there was no way CPV’s can be installed onto your rooftop or even in your backyard, depriving them of large profit loss with unmarketable products; but this changes now. CPV researchers have found a method to downsize CPV for rooftop installations, reviving an untapped market that was winding down.

Rooftop CPV’s: To make more use of it, shrink it

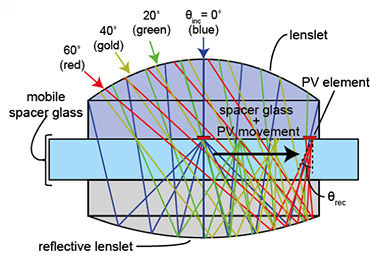

Scientists at Pennsylvania State College are now producing microscale concentrated photovoltaic cells with a translation-based tracking scheme that was invented back in 2010. The fabrication process includes growing and separating micro-PV’s and 3D-printing the final cells onto a thin glass sheet. The layer is then placed between lubricated refractive and reflective lenslet to allow for sliding, tracking, and re-adjusting.

The result: a concentrating photovoltaic panel about 1 centimeters thin, converting 200 times the sun’s concentration, and actively tracking 8 hours a day. When tested out in the field, the system demonstrated a concentration of roughly 100x, a fraction lower than projected due to defaults in the 3D-printing process. Still, we could do with 100 times the power of the sun on our rooftops; with the new power conversion efficiency rates at nearly 50%, rooftop CPV’s beat current flat panels twice over, generating more natural power, decreasing grid dependence, and in monetary terms, resulting in more returns on feed-in tariffs.

At this point the question of cost arises: will rooftop CPV be affordable? Affirmative, expressed Penn State engineers:

“…inexpensive acrylic-plastic lenslet arrays combined with manufacturing-scale microcell fabrication and transfer printing provide the requisite ingredients for a low-cost system.”

Indeed, as everything except solar cells and transistors can be made out of cheap acrylic materials, micro-CPV should be available at minimal costs. Practicality— check.

Looking Forward

Though rooftop CSP’s hold great promise to commercial solar sphere, they are still very weather-dependent. However dynamically constructed, concentrators will have little to focus without direct sunlight. And the aspect of unpredictable supply is a problem shared by all clean energy initiatives—wind, solar, heat, and gas. Total reliance on any one technology still awaits major developments in energy storage. What may be more practical is a hybrid model leveraging everything nature has to offer. And why not? It would make a solid clean energy solution for households and on-site, bringing us closer to a world powered by nature than ever.

![How to Handle a Project Management Crisis [Infographic]](https://technofaq.org/wp-content/uploads/2017/01/project-management-crisis-150x150.png)