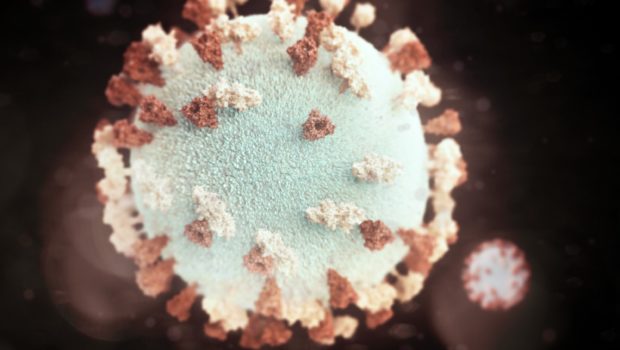

3D Printing Community is responding to the COVID-19 pandemic

In the recent past 3D printing has carved its niche as an invaluable prototyping tool for significant industries such as biotech, architecture, prosthetics, etc. However, this vibrant community of designers and printers have struggled to break out from a technology niche tool into a household name. Queue, COVID-19.

Since the outbreak of the global pandemic we have witnessed a spike in demand for medical equipment required to fight the virus. Most countries are facing a severe shortage of this essential medical equipment, which includes valves, face masks and shields, testing swabs, and ventilators. Besides, other sectors and tech security have also had their fair share of challenges.

While the need for a total lockdown has crumbled traditional production and supply chains, we have seen the tech companies and the entire 3D printing community swiftly respond to this shortage. By sharing, equipment designs, and pooling resources, there are ways in which the 3D printing community consisting of companies and individuals are responding with stop-gap measures during the Covid-19 crisis.

3D Printing Manufacturing Giants Are Rapidly Providing Medical Equipment

Leading 3D companies all over the world, such as HP, General Electric, Johnson & Johnson, etc. have joined hands via a 3D Printing COVID-19 Rapid Response Initiative forum. The forum is set up to cater to challenges arising from shortage of equipment and increasing medical demands as the pandemic gets to its peak. Although faced with standardization, certification, and 3D design modification, most of these companies are striving to provide support for medical devices such as:

Testing kits

US-based company Formlabs is responding to the need for the rapid development of testing kits. Formlabs is achieving this by enabling printing of 300 swabs at once on one 3D printer. The community response to the Formlabs Support Network for COVID-19 has been tremendous. In the first 48 hours, Formlabs received almost 500 responses from individuals and organizations showing interest. Formlabs is currently working with some medical and healthcare organizations to support their COVID-19 specific projects.

Also, Carbon fibre and metal 3D printer manufacturers Markforged is partnering with Neuralphotometrics, to help rapidly develop a 3D printable swab test to ease the shortage caused by the COVID-19 pandemic. Markforged says its clinical validated test swabs are designed pairing a 3D printed nylon swab base with a wrapped rayon tip. The prints are produced in minutes at 10 000 units of swabs each day. The aim is to increase this to 100,000 per day.

Ventilator parts

Italy, one of the hardest-hit countries during this pandemic, got some rapid response from Isinnova, an Italian 3D-printing start-up. The company started immediately printing much-needed Venturi valves when hospitals began running short on valves. These Venturi valves are designed to help a patient with breathing problems by changing the oxygen and airflow on their respiratory masks- difficulty in breathing being one of the significant symptoms of coronavirus patients. The 3D start-up was able to deliver 100 of the valves to a local hospital and is currently working on designing CPAP masks into snorkel masks that use positive air pressure that opens up patients’ airways.

Linde plc offers combined 3D printing (metal and plastic, design, and software) and medical equipment capabilities in Germany and the US. Furthermore, rather than investing in printing time and materials, more open-source 3D projects are on the rise with the ultimate goal of developing cost-effective and locally made ventilators. Thanks to Brent Jackson of the OpenRespirator Project, you can find several 3D design fabrications of intubation devices.

Door opener

3D printing community has also helped with less high tech devices, such as door openers. These door openers are crucial in containing the spread of the virus. One company actively responding is the Belgian 3D printing bureau Materialise. They have designed a 3D-printed door opener that makes opening and closing of doors possible with your arm, so you don’t need to touch door handles. With access to a 3D printer, all you need to do is download the design and 3D print it for free within a few hours. So far, the model has 30,000 downloads.

Additionally, Barcelona’s CIM UPC has also designed a simple home printable door opener to aid the hands-free opening of doors. CIM UPC’s version only requires cable-ties to attach to the door handle, and it opens.

Face masks and shields

Similarly Italian 3D printer manufacturers Roboze, is also exploring ways to make masks. The company has a high-end FDM system that is PEEK (polymer material more commonly known in the world) compliant. Likewise companies in Canada such as 3D printer manufacturer Tinkerine, have diverted their production facility to cater to face shield production.

In the US, manufacturers Ford Motor have put all their facilities in the country to work on 3D printed PPE, including its in Plymouth, Michigan that is equipped to produce roughly 1,000,000 face shields weekly. Additionally, Czech RC3 face shield designers, Prusa Research have been able to gather vital data on successful sterilization methods for 3D printed personal protective equipment. While collaborating with other Czech laboratories, research institutions, and organizations, the company’s face shield underwent several rounds of sterilization using different methods and chemical agents against Covid-19-positive solutions.

3D and Architectural Building

Another response of the 3D community to COVID_19 impact involves the use of large-format 3D printing to produce structures at a rapid pace with limited materials across the globe. Companies such as SelfCAD and Inov3d are making it much easier for architects and designers to create and share these makeshift structures.

As hospitals run out of beds and the growing need to create more intensive care units, governments need to act speedily. Rather than converting existing buildings into treatment or isolation centres, some 3D designers have decided to develop brand-new systems for emergency intensive care. One of such examples is Connected Units for Respiratory Ailments. CURA is an open-source 3D design solution for emergency COVID-19 hospitals. It was initiated by a team of architects, doctors, engineers, and military experts, and it’s currently being built in Milan, Italy.

These pods are designed using repurposed 20-foot long shipping containers converted into bio containment pods and are easily moved within cities around the globe. Each unit in the pod functions on its own, and individual pods can be connected by an expanded structure to create modular configurations. The pods contain equipment and ventilators needed for two patients. The best part about the design is that it can be deployed in just a few hours in self-standing field hospitals or designated spots such as parking lots.

Microsoft Artificial Intelligence for Health Initiative

Microsoft Corporation’s AI for Health initiative is providing medical researchers with the necessary computing power to battle the virus. It has set up a C3.ai Digital Transformation Institute and dedicated $20 million in grants to receive open calls for proposals designed to mitigate the COVID-19 epidemic using artificial intelligence and machine learning.

Collected and analyzed data will be freely available via an open data access portal. This portal will be open to researchers, public health officials, or organizations, including the 3D printing community around the world. Furthermore, Microsoft has partnered with the CDC on an automated system that enables anyone to check their symptoms. Users can check their symptoms on their own, so the burden on health services is mitigated.

Additionally, Microsoft is working with local groups in places that have been hardest hit by the virus to help them continue business and educational operations for companies and students. Besides offering the best deal on Microsoft Office, Microsoft is providing online initiatives to foster global learning during the pandemic. So with more learning initiatives from UNICEF and Microsoft and resources such as Pick The Writer writing service review, students do not lose out on their academic year regardless of the disruptions caused by the virus.

Conclusion

As the world battles with this novel virus, it has been riveting to see how the 3D community has risen to the occasion to proffer solutions that will be useful even beyond this epidemic. As hospitals, healthcare authorities, tech companies, architects, and manufacturers in other sectors take delivery of equipment printed locally and on-demand, 3D printing could help to cut down delivery times and quickly scale-up production in times of need.