Top Disrupting Industrial Robots Trends That Will Shape the Manufacturing Industry

The manufacturing industry is staring at a major revolution—characterized by innovations. With the invention of automation, the manufacturing industry looks set to benefit immensely. Automation will change how materials are handled, processes are done, and tasks are executed. On these lines, here are top robotic disrupting trends that looks set to transform the manufacturing industry.

Adoption of AI

For many years, people have hugely invested in sensor and data technology. But it’s high time for those investments in advanced analytics to come together with AI (Artificial Intelligence). AI can be applied to boats, cars, drones, warehouse robotics, as well as other vehicles. And very soon, robots would become an incredible source of information on the factory floor. With the increased adoption of robotic automation, the need for open automation architecture is also escalating. Industry players will need to join hands so as to create open documentation to make robotic integration simpler and more compatible.

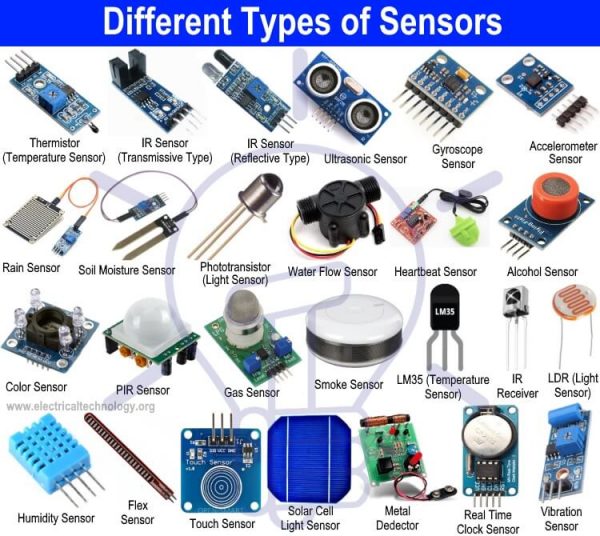

Sensors

With the escalating demand for automation, most companies would soon need to invest in a new type of infrastructure. In the near future, autonomous will need advanced laser scanners to navigate roads, particularly when there’s snow that might hide lane markings. Even more, smart sensors make it easier for robots to navigate and collect information to help humans. Aside from this, the incorporation of 3D cameras would provide enhanced precision and capacitive skins could as well be wrapped around robots to make them touch-sensitive.

Developing Logistics

Most companies are now launching new products across different platforms of the logistic value chain, including self-driving trucks, intelligent warehouse, and service robots. Until recently, robots were widely utilized for packaging and pick-and-place. Nonetheless, the incorporation of sensors with robots as well as self-driving vehicles will help them to easily navigate the factory floor. And this will, in turn, bring down costs and improve quality. According to research, automated systems can help improve workflow and reduce about 68 percent of errors caused by humans.

Collaborative Robots

Collaborative robots are the next phase in industrial robotics. They are likely to hugely benefit the manufacturing industry. These devices can safely work alongside human beings and are expected to be extremely affordable. Because of this, they’d easily be adopted by manufacturing companies with strict ROI restrictions.

Key Takeaway

Manufacturing is evolving. It’s attracting new technologies. For instance, automation is making manufacturing smarter and more efficient. The above trends are poised to take the manufacturing sphere to another new level. So, don’t be left behind. Automation is a new trend in town. It will not only give you efficiency but also accuracy.

The Bottom-Line

It isn’t rocketing science to figure out that robotic technology would disrupt the manufacturing sector, but the truth is that it would still take a few years to see industrial robots functioning with full potential. Nevertheless, with innovative and adaptive technologies like smart sensors and Artificial Intelligence, the future looks exciting for industrial robotics. In fact, their era has just begun. Invest in a FANUC robot today and take your game to the next level.