The great potential of 3D printing in the PCB industry

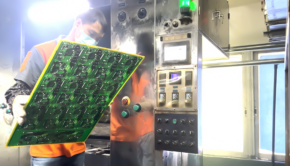

Lately, 3D printing has established its relevance in enhancing manufacturing processes and is currently dominating the manufacturing industry. Additive manufacturing or 3D printing is evolving the world into the possibility of 3D printing just about anything, and it is making an unprecedented entrance into the realm of PCBs.

Although 3D printing is at its infantry phase in the PCB industry, it proposes a great deal of potential moving forward. The application of 3D printing will solve the biggest pain points of PCB manufacturers and designers.

Why the PCB Industry Needs the 3D Printing Manufacturing Process

The current procedures for producing PCBs are undoubtedly a rigorous one; from drilling, copper etching baths, hiring subcontractors overseas, mining, film transfer, testing and redesigning. This takes weeks and even months to complete.

An itsy mistake whilst manufacturing PCBs can compound into a bigger problem, as the quality of the PCB Design can suffer and eventually need a redesign.

After producing and testing PCB prototypes, issues could arise and glitches have to be rectified, which are usually known later on in the design cycle. All these will further increase the cost and will definitely be time-consuming.

However, the use of 3D printers will accelerate the capabilities of creating a highly functional proof of concept prototype at a fast-paced rate, thereby facilitating the creation of multiple prototypes.

Manufacturers and PCB designers can rapidly build and spit out fresh PCB prototypes in house, test it and send it out in a matter of hours. This process dumps the traditional tedious processes, and also makes use of very minimal resources, saving two highly valuable things: time and cost.

This will make decision making easier and knowledge of whatever glitches promptly detected and fixed, thereby making the PCB design process less daunting and minimizing mistakes as much as possible.

There is also the risk of sending intellectual property to companies overseas due to the confidentiality of IP addresses. One of the core benefits of using 3D printers is removing the need for hiring specialist contractors overseas to aid in PCB manufacturing, which is risky as it is done off-site.

With the innovation of 3D printing, every process of building PCBs is done on-site or in house. It will bring alongside a myriad of benefits that will completely revolutionize the landscape of making PCBs.

The Vast Benefits of 3D Printing Application in PCBs

There are abundant benefits of using 3D printers for producing PCBs which will only keep growing as more developments are made. The application of 3D printing will bring about the possibility and flexibility of printing PCB prototypes at a fast pace to manufacturers for in-house development.

Rapid prototyping will go a long way in saving time, cost and labor requirements whilst designing PCBs.

3D Printing allows PCBs to be manufactured in-house which gives birth to a myriad of possibilities. It serves as an opportunity for designers to be more creative due to the reduction of time in the development process.

Another advantage of 3D printing is allowing PCB testing by sections; depending on the manufacturer’s preferences, even complex and customized designs can easily be produced in a very short time span. The final product is promptly ready to be put through a PCB test engineering.

It also provides the capability of producing unlimited PCB design shapes which are highly needed in today’s world of IoT devices and the trend of PCB miniaturization.

Additive manufacturing will bring about improved product performance, the ability to experiment widely and give room to easily redesign while also elevating the performance and efficiency of PCBs.

The use of 3D printing will go further as letting circuits get printed within objects and still perform effectively. One of the great features that 3D printers pose to give is the ability to insert embedded components into the PCB to utilize a versatile range of technologies.

The use of 3D printing will also enable PCB designers to work simultaneously on all design projects. This will enhance their productivity and ensure efficient utilization of resources.

This takes the pressure off PCB designers to complete tedious projects within a specific time frame, saving them intensive labor and enables them to channel that effort into being more creative compared to worrying about utilizing every inch of board space efficiently.

It will further enable flexible hardware methodologies, which are highly relevant in this age of wearables and give PCB manufacturers a competitive edge.

Furthermore, on the benefit of accuracy, which is one of the biggest selling points of 3D printers, its application will also help in evaluating the design in comparison to the intended design performance and fully matching the specifications.

Conclusion

The electronic industry is becoming highly competitive, and manufacturing highly sophisticated PCBs is now the norm, thanks to the continuous advancement in technology. This results in the need for a better and more efficient time in the market of PCBs, due to the increasing need for a shorter and more efficient product development process.

The integration of printed electronics into 3D structures will transpire into better functionality and faster design process in the PCBs. Additive manufacturing will transform the outcome of PCB designs, and revolutionize the manufacturing processes.

3D printers will facilitate manufacturers to hastily conclude the concept design of the PCB in its initial phases of development, speeding the PCB manufacturing process and ultimately prioritizing customer demands.

As the turn-around time for producing PCB prototypes for release becomes shorter at all stages, it gives room for testing and receiving immediate feedback thereby achieving better results.

And ultimately, revealing potential deficiencies early on is a huge time saver and quality enhancer.

All these are made possible through the use of 3D printers, but there is a lot of work and developments that need to be made to be able to fully utilize the advantages of additive manufacturing in the future. Therefore 3D printing should be prioritized in the PCB industry.