Introduction to CNC Machining

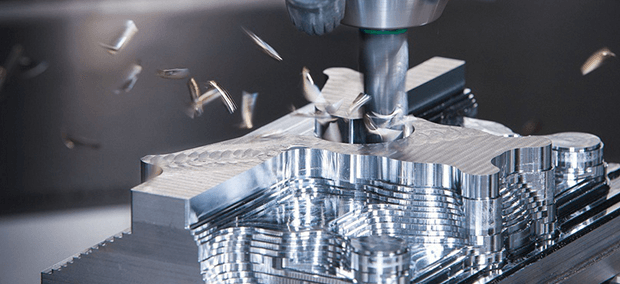

CNC Machining is frequently the last step in metallic manufacturing, sometimes the only process involved. Compared to different metalworking techniques, CNC machining can meet the tightest endurance and producing the many accurate, fine products over and over again.

It is important to break the passage down into two different parts:

- First, the process of removing all metal with the assist of automatic equipment has been around for centuries. Machining process include: broaching and grinding, shaping, turning, drilling and milling,

- Next one is NC is an abbreviation of Numerical Control in old machining; an operator must control the motion of a machine tool. Numeric control, first developed in the 1940s, governs the motion of machines mechanically, through the set instruction manual.

History of CNC Machining

In the 1940s, John Parsons of Parsons Corp. in Traverse City, MI, make this system to control machining instrumentality by feeding it punched cards with holes similar to coordinates. Started in 1949, Parsons joined the U.S. Air Force at an MIT laboratory to develop what was to get on numerical control. https://artmachining.com/cnc-machining-services/

The team in back-end numerical control formulated a process to produce aircraft parts that needed a high degree of precision and took non-automatic operators hours to work through with the improvement of numerical control, parts produced had little human oversight.

The Most Advance of CNC Machining

A punched tape reader on a CNC machine control Shared through CC 3.0 by Wiki user Three Quarter Ten Patch early NC scheme were radical in their own right; there was still plenty of room for betterment. For starters, machine tools had to have a program using a boring process, and errors were common. Antithetic companies developed many different programming languages, resulting in disorder and inconsistency that, at very first, stymied the growth of NC machining.

The United States Air Force stepped in again, funding research at MIT to develop a universal Numerical machine programming language, in 1959. Versions of the programming language, called Mechanically Programmed Tools are still in use today. At that time, with the fast growth of engineering, early NC machines were controlled by tiny computers attached to each machine. Today you can buy cutting edge automatic CNC machinery from Revelation Machinery that is not only more simpler but more advanced as well.

The Great Future of CNC Machining

As world demand for CNC machined products fast grows and daily changes, a wide variety of introducing are currently taking place in the CNC machining industry.

- Robotics – more than only mills and lathes, CNC is progressively being applied to commercial enterprise robotics. In many factories, machines not just handle work like cutting and welding, but also assembly and transportation.

- 3D Printing – a competitor to CNC machining and a complementary process, commercial enterprise 3D printing is also growing quickly. While machining is an ablative process–starting with solid stock and edged away material to form a shape–3D printing is accumulative. In many cases, the mark can 3D print a prototype, and use it as a shape to configure CNC instrumentality. In other cases, products can be inaccurately, and precisely 3D printed straight from design software.