How Industrial PCs are different from Regular PCs

There are two significant reasons why industrial computers are categorized differently. First, they are designed specially so they can withstand harsh industrial environment – including factors like vibration, high shock, dusty environment, extreme temperature range, and exposure to toxic liquids. Secondly, they have more extended life-cycle support as compared to regular PCs.

Source

There’s indeed, a lot of difference between the regular consumer PC and one that is designed for industrial purposes. And if that’s the information you are looking for, you are at the right place.

Industrial computers vs. regular computers: All that you need to know

There are significant differences when it comes to applications. However, most industrial computers consist of the basic components just like the regular computers. These include a CPU, motherboard, memory, keyboard, hard drive, graphic-cards, displays, optical drives, mouse, etc. It is just because of the special application for industrial environment, which gives industrial PCs their unique characteristics.

To match the specific nature of the industrial environment, some of the exclusive characteristics that most industrial computers possess include:

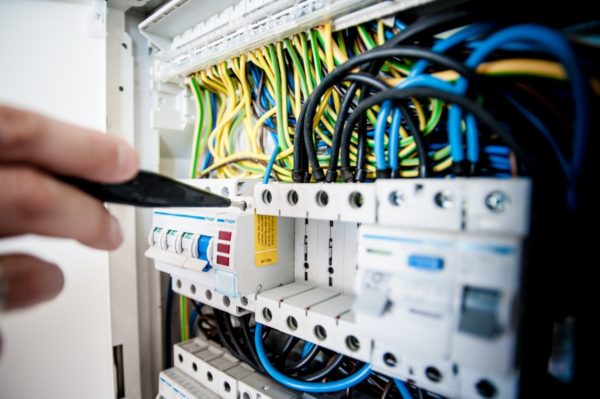

- Designed according to the guidelines of ‘EIA’ – the standard steel chassis for the chemical industry. This enhances the hardware of the system to resist electromagnetic rays and interference.

- Customized modular and architecture design techniques. The functional modules of the CPU are based on a plate structure, with rubber-lock layering to improve vibration and impact resistance.

- Based on high industrial power, and overvoltage.

- Keeps up with over current flow.

- Works with keyboard lock as well e-power supply to avoid off and illegal keyboard input.

- Usually includes a ‘watchdog timer’ in case the system crashes without auto reset or human intervention.

- Incredible compatibility and openness towards a great variety of software applications.

- Based on the real-time operating system, which can be configured as per the specific industrial needs.

- Easily upgrades through the passive motherboard.

As far as receiving, processing, and storing information is concerned, both industrial and regular PCs would be similar regarding operations. However, the fact that industrial PCs are designed for a more rugged environment, they are different with regards to performance, expandability, compatibility, reliability, and availability.

Naturally, industrial PCs are expected to excel in dirty, harsh, and aggressive environments. They should perform well under severe conditions. Other than the factors mentioned above, the following are some more common factors you will find industrial PCs different from the regular ones.

Vibration and Shock

A regular PC may not be able to withstand high levels of shocks and vibrations, which are common in an industrial environment. The ruggedness and mechanical stability of an industrial PCs ensure they can perform regardless of the constant vibration. Such PCs can even tolerate shocks as high as 5G.

Humidity and Dirt

The hardware design of industrial PCs may include multiple cooling fans. These are not only essential for regulating the heat but also keeps the dirt out. The filters installed with the cooling fans are tested in tough conditions to ensure they only provide clean and direct airflow for internal cooling. A regular PC may not include such fans or filters.

High Temperature

A wide range of severe temperatures can be normal conditions within some industries. This means excessive heat or icy conditions, which can easily take a toll on a regular PC. However, the rugged industrial variations can perform under such temperature conditions without losing the hardware lifespan.

For industrial PCs, operating in temperatures are as much as 55 degrees C can be a norm.

IP Rating

Unlike regular PCs, you can expect industrial PCs to provide IP protection. Most industrial designs offer protection against contaminants for water and dust resistance. Stainless steel and aluminum ranges can opt for.

Electromagnetic Interference

Industries operating with huge motors and machines may have electromagnetic interference. Such sharp rays may interrupt communications between equipment. It is also a major reason behind sudden voltage spike that could destroy electronic equipment and components over time.

When designing PCs for such industries, it is important to ensure it is equipped with stabilized voltage and robust isolation features.

Final Word

Other than the features, the cost consideration may also vary greatly. For industrial setups, the cost consideration could be way more than just the initial investment. In addition to a bigger price tag upfront, the overall ownership cost can also be huge as compared to regular PCs.

About the author:

Alycia Gordan is a freelance writer who loves to read and write articles on healthcare technology, fitness and lifestyle. She is a tech junkie and divides her time between travel and writing. You can find her on Twitter: @meetalycia