How a Company Used Aluminum & CNC Machining to Manufacture Automotive Reflector Prototypes

Nowadays we have grown used to hear about 3D printing and how it can build anything by adding layers on top of the other. However, an older, more common, and one could even say more optimized, rapid prototyping technology is CNC milling. It is a machining process that dates back the 19th century, and to this day, every day, you will come in contact with something built through this milling process. Today, we are discussing how very recently a company called WayKen (a CNC milling service in China) is using aluminum and CNC machining to produce automotive reflectors prototypes.

CNC Machining

Source: shutterstock.com

But first… Let’s begin with a brief introduction to what CNC milling actually is, so everybody understands the concept before we dive in into further details.

Milling is the process of using cutting tools to mill away layers of material from a workpiece (contrary to 3D printing where it adds layers). This process begun from the 1810s practice of rotary filing. During the World War I milling was greatly developed and saw many breakthroughs in its technology, setting the groundwork for the CNC milling we know today.

CNC Machining is a type of milling, also known as machining centers, CNC stands for ‘computer numerical control’; automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. The components are designed in CAD (computer-aided design) software, everything from dimensions, surfaces, 2D and 3D spaces, materials, etc. Afterwards, they are imported into manufacturing directives by CAM (computer-aided manufacturing) software. This program translates the design into specific commands which are than loaded into the CNC machine and begin the process of manufacturing.

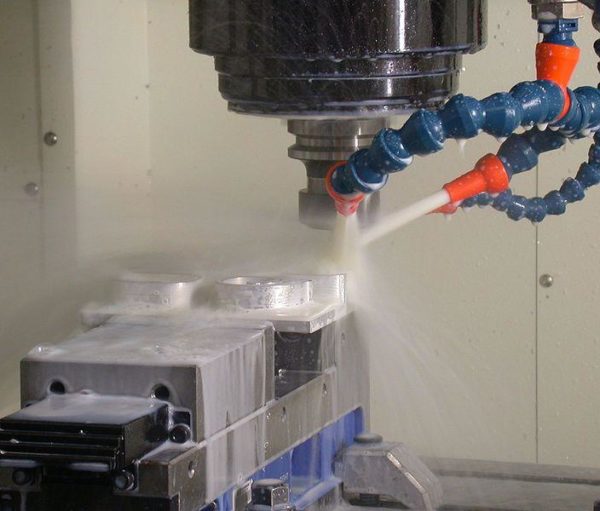

Another characteristic is the computer controlled vertical mills with the ability to move the spindle vertically along the Z-axis. Thus, enabling more freedom, precision, and speed. There are many types of CNC machinery, but we won’t get too technical.

Interesting Fact: CNC Machines are now cheaper than ever, thanks to new CNC open source software.

Milling of aluminum using a water based cutting fluid on the milling cutter

Source: wikipedia.org

What are the usual steps until I achieve the final result (producing the ‘part’)?

It goes without saying only a qualified professional should operate this type of machinery. In fact, it’s a profession in high-demand. But let’s cut to the chase, what are the normal steps in producing a piece through CNC milling:

- Define if you are mass producing, manufacturing small batches or even one-of-a-kind items.

- Analyze the drawings (produced by the engineer) and follow the blueprint.

- Create and develop the project in a CAD/CAM system (and/or F and M-codes).

- Assemble the tooling, the holding device, and the workpiece on the CNC center.

- Configure things such as the cut, shape, speed, etc, according to the blueprint and/or other conditions fit to the specific task.

- Operate and do maintenance real-time during the process to maintain dimensions and other details within the respective characteristics.

At the beginning of this article we told you, very basically, about the two major differences between CNC machining and 3D printing, while the first cuts material the latter adds. What we didn’t tell you is that these two technologies can complement each other. In fact, many companies use CNC machining to finish 3D printed parts. This is what WayKen, a CNC milling service in China, is doing to build automotive reflectors.

WayKen is a Chinese company located in ShenZhen that focus on plastic prototypes and metal machining. It is one of China’s most experienced prototype manufacturers, including CNC Machining service, rapid prototyping, rapid tooling, vacuum casting, molding, etc. Recently, the company has widened their areas of work by focusing more on automotive prototyping, since the car industry is one of the biggest users of 3D printing + CNC machining technology. One of their most recent projects is building automotive aluminum reflectors, and CNC machining is the best technology to accomplish the needed results.

“Among all the rapid prototype projects I know in lighting system, aluminum reflector is one of the most challenging works” – WayKen blog

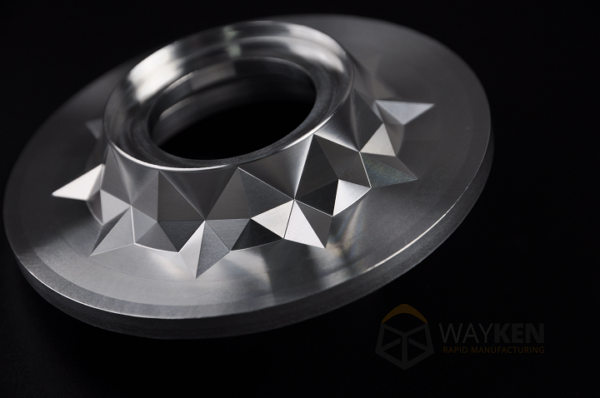

Building an Aluminum Reflector

Source: waykenrm.com

Why CNC Machining is Ideal for the Automotive Industry and Building Aluminum Parts?

There are a wide range of benefits in using CNC mills to build car parts, not just according to WayKen, many manufacturers find this technology to be perfect for this purpose. This wide array of benefits is:

- Speed – As expected, the whole process is very automated, thus allowing for mass production without sacrificing quality.

- No Errors – Computer numerical control helps the operator optimize the whole process and produce error-free parts. Modern CNC software ensures efficiency and simplicity.

- Low Labor – The whole process is highly automated, in fact most CNC mills only require one machine operator when it comes down to actually mass producing the parts.

- High Precision – Prior to CNC development, manual milling resulted in faulty outcomes, however due to computer numerical controls the machines can cut materials with millimeter precision, thus enabling the production of aluminum parts (requires very high accuracy).

- Multiaxis Linkage – Computer numerically controlled cutting tools that move in 4 (or more) ways. They mill away excess material, by water jet or laser cutting.

“Good surface roughness is often required, generally lower than Ra0.2μm and needs to be mirror gloss. The normal SLS and other rapid prototyping processes cannot meet the surface quality requirements. Besides, as an important optical component, the accuracy requirement is controlled within or below 0.05mm. Therefore for machining aluminium reflector, CNC milling is the best option, its advantage is embodied in machining the parts with high precision, and the surface of CNC milled parts is high quality.” – WayKen Blog

CNC Aluminum piece

Source: waykenrm.com

Aluminum reflectors pose a great challenge for manufacturers, these types of reflectors are often used on higher end cars. The reason why it represents such a challenge is due to its complex structure and high precision requirement. So what was WayKen’s process?

In the auto industry rapid prototyping manufacturers have a wide range of processing options for each part. This variety of processes allows them to focus on what’s truly important to each part. Some examples of this processes are 3D printing, Urethane casting, RIM (Reaction Injection Molding), and rapid tooling. According to WayKenRM blog, they have used CNC milling process because it’s the best option for machining aluminum reflectors, because:

“Good surface roughness is often required, generally lower than Ra0.2μm and needs to be mirror gloss. The normal SLS and other rapid prototyping processes cannot meet the surface quality requirements. Besides, as an important optical component, the accuracy requirement is controlled within or below 0.05mm.” – WayKenRM blog

As we mentioned previously, high precision is one of the most important benefits of using CNC milling. This ensures the aesthetic of the part meets the optical requirements of a product in an industry where appearance is very important. Everybody wants a good looking car without faulty parts.

Aluminum is a highly durable, lightweight, easy to mold material, it is a non-ferrous metal and one of the most resistant to corrosion. It is also a great conductor of heat and electricity, and a good reflector of light and heat. Therefore, ideal for automotive reflectors; widely used in the car industry.

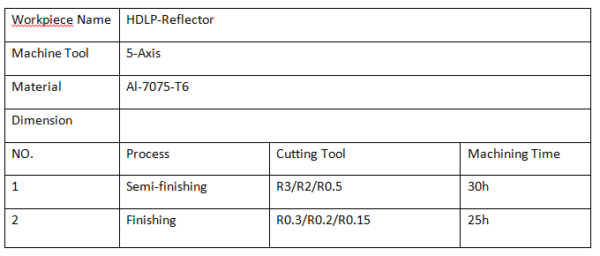

The CNC Machining Process

Source: WayKen blog about the entire process

WayKen uses a wide variety of different types of aluminums to achieve their perfect outcomes. An interesting fact about WayKen is that they also use aluminum prototype CNC machining for manufacturing other types of components, other than the car industry. Some of these components are also used in drones. Although the machining process is of course different.

Advanced rapid prototype manufacturing and CNC machining services Sunshine Coast cover a wide range of industries. From cards to UAVs (Unmanned Aerial Vehicles), both benefit a lot for this type of rapid and low-cost manufacturing. Design, presentation, engineer, verification, low-volume. Everything is covered and especially made to enhance the quality of the final product.

Interested in becoming a CNC machine operator? Are you already a student of this craft?

We have a fun fact to share with you. CNC milling is also available at a very small scale (such as a hobby), to produce one-a-kind pieces. It is nothing compared to industrial CNC machining, of course. However, if you are interested in trying it out as a hobby, there are some home CNC milling machines available in the market. Many people use it in their home shops to produce small objects.

Example of a very simple, non-industrial CNC machine

Source: Amazon.com

These of course still must only be operated by a professional. But it is a useful tool to give your first steps if you are a student of the craft. It is a simple and yet interested home tool to practice basic CNC machining and manufacture some simple pieces.

Would you like to read more about this subject? Let us know in the comment section below. Also, don’t forget to share your input and experiences on this subject. If you found this information helpful share it with your friends and social media. Have a great day!