How General Electronics Is Reinventing the Electronics Switch

For years, GE (General Electronics), the American multinational conglomerate has been using electronic switches to control the circuits inside the medical equipment it sells to hospitals. However, the company has revolutionized electronic switches and looks forward to making them available to a larger audience.

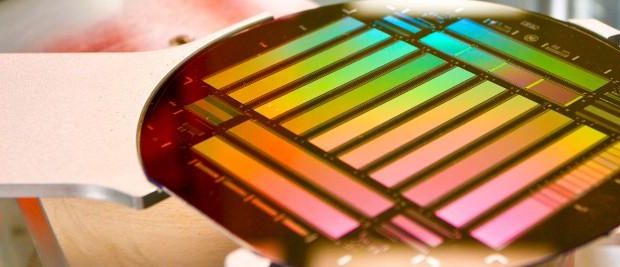

(Image source)

Menlo Micro, which was launched with the aim to re-invent the electronic switch, is the brainchild of GE’s Global Research Center. The launch of Menlo Micro was supported by Microsemi, Corning and the Paladin Capital Group. The new company was launched with the goal of commercializing the MEMS-based (micro-electromechanical systems) switch.

The Case of MEMS Switches

We are all familiar with the typical switch and use it all the time. It is a simple device, which when moved to the ‘on’ position, establishes electrical connection between the power source and the device (fans, lights, computers, medical equipment, etc.), enabling the device to function.

However, scaling down the size, the weight and the cost of switches was necessary to support new-age technologies. Switches also needed to function faster and more reliably in extreme operating conditions, but there had been no change in this technology even though scientists had been trying their best.

However, scientists at GE’s Global Research Center were able to develop the revolutionary MEMS digital switch, which can be used in automated test equipment (ATE), next generation 5G mobile handsets/base stations, aerospace operations, industrial Internet of Things (IoTs), electric vehicles, battery management, home automation, and medical instrumentation applications. GE claims this switch to be the industry’s first reliable MEMS digital switch and it has successfully been field-tested with over 35,000 units in GE systems.

The USP of the new MEMS digital switch is that it operates with low resistance and low losses. It also helps in reducing the heat produced and in enduring billions of switch cycles. Previous attempts of commercializing MEMS switches failed due to the lack of reliability and manufacturability issues. Menlo uses a new approach in designing the switch, thus improving the reliability factor, thanks to GE’s decades of experience in hi-rel (high reliability) markets like jet engines and gas turbines.

The Basics of MEMS Technology

MEMS, also known as Micro-Electromechanical Systems, is a technology that enables the creation of miniature mechanical and electro-mechanical elements on a silicon strip using micro-fabrication technology.

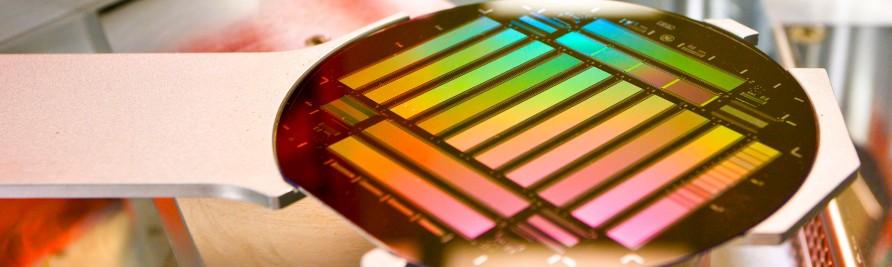

(Image source)

The dimensions of MEMS devices vary from less-than-one micron to several millimeters. MEMS devices include elements that have some sort of mechanical functionality regardless of whether or not they can move.

The major components of MEMS device are miniaturized structures, actuators, sensors, and microelectronics, but it is the micro-sensors and the micro-actuators that play critical roles. These devices are capable of converting one form of energy into another. The real potential of MEMS is unleashed when the miniaturized sensors, actuators, and structures are combined with the integrated circuits on a common silicon substrate.

The benefits of MEMS technology include:

- MEMS supports miniaturization of existing devices.

- MEMS offers solutions that can support modern technological advancements.

- MEMS improves the reliability, performance, cost, and ease of use of electronic devices.

- MEMS technology’s micromachining techniques and its interdisciplinary nature allows it to collaborate with a wide range of devices across previously unrelated fields.

Considering the potential of MEMS technology-based micro connectors, an increasing number of technical solution providers are adopting it for creating miniature devices in the future. Technology solution providers are now using MEMS and EFF fabrication techniques along with Board-to-Board interface connectors to solve pitch-size problems that are commonly associated with commercial designing of miniature devices.

How Menlo’s MEMS Switches Are Different from Others

Being a power and technology company, GE used numerous switches for operating the range of devices that are used across various industries. But the traditional mechanical switches were bulky, expensive, drew a lot of current, and dissipated a huge amount of heat. In order to improve the performance of the devices, GE started looking for providers of remotely programmable circuit breakers. The switches available were not reliable, which is why GE took it upon itself to solve this problem.

Their team of scientists, metallurgists and semiconductor physicists worked together to create a new material that solved the problems. Other than the new material, Menlo’s MEMS power switches use the same fixed unit cell, a micrometer-sized cantilever beam with an electrostatic actuation that establishes an ohmic contact at its tip. By combining several such cells, the startup became capable of changing the voltage or the current-handling capability of its devices.

The best thing about the new switches is that they can be manufactured at a lower cost compared to solid state switches, and several variants of the product can be designed without hindering the reliability of the cell. According to Russ Garcia, Menlo Micro’s CEO, the new technology has allowed the company to create something that can be considered the ‘ideal switch.’ However, Garcia also admits that solid state switches are the best option if you need to switch in nanoseconds; but if you have anything that needs to switch in microseconds, then MEMS switches can be a great solution.

Conclusion

GE is Menlo Micro’s first product, customer and it has successfully used the MEMS switches in its MRI systems. However, the company has to make further improvements to the switches before making them available to the masses. A lot of product development activity is yet to be done and GE will continue to invest in the company.

About the author:

I’m Rachel Oliver, I have been working for the past couple of years as a freelance writer and currently associated with Scondar. While I like to write about all things under the sun, including business, technology & gadgets, and electronics. You can get in touch with me on Google+, Facebook and Twitter.