Here’s Why Working With CNC Machines Is The Best Option

The industrial revolution changed the way we lived our lives. Constant developments in the world of manufacturing are shaping the future and how companies produce products. The computer, one of the most remarkable inventions of the last century, has played a huge role in changing the old ways of product manufacturing.

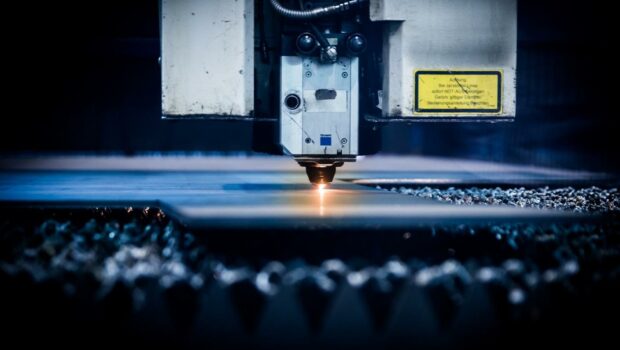

The first CNC machine was invented in 1952 and has been incorporated widely in the industries. Manual machining can never match the accuracy, productivity, efficiency, and safety of CNC machines – keep reading out more on why CNC machines are the best option for manufacturers right now!

Superior Accuracy

Accuracy is the most important part of any manufacturing operation. If a team of laborers cannot work accurately by the guidelines, it will destroy the reliability of a company’s products in the market. Manual machining can never be free of errors, and there’s no telling when you will encounter faults in your manufactured products.

On the other hand, CNC machines have superior accuracy and help a manufacturer produce amazing products repeatedly. Trusted CNC machines like SIEMENS CNC are known for repeating a task without making any mistakes in the manufacturing process.

Fast Production

A manufacturing plant has to produce the maximum products it can in a given timeframe. Spending extra time on a task that should not take more time increases the production costs, making it difficult for a company to compete in the market.

The usage of CNC machines allows companies to produce products at a faster speed. Computer programs don’t take additional time while executing and ensure that a given process takes less time than manual machining. CNC machines can work for extended hours without any breaks, which multiplies the productivity of a manufacturing plant several times.

Increased Safety

One of the biggest perks of introducing CNC machines in your manufacturing plant is that they provide superior safety to your workers. Manual machining is never free of any safety hazards. Gone are the days when manufacturers could go away with abusing their employees. Now, governments keep the manufacturers in check to ensure the safety of workers.

Your employees can use the CNC machines from transparent safety doors. Some CNC machines have a special guard which protects your employees from any potential dangers. Compared to manual machines, CNC Drilling Machine Perth pose almost no threats to your important employees.

Cost-Effectiveness

Cutting costs is essential for every manufacturer nowadays. Given the fierce competition among companies in the market, only providing the most affordable products can increase sales. CNC machines help manufacturers to lower their operational costs without compromising on quality. Using CNC machines ensures that you are not wasting your money producing faulty products.

A single operator can easily handle several CNC machines without lowering the supervision and quality standards. Manufacturers can also save their costs by using solar energy to use CNC machines. Using these machines also allows manufacturers to limit the waste by employing a smooth and error-free production strategy. Hopefully, you’ve learned something beneficial about CNC machines after reading this article and if you love to learn more, you can visit the MRO Electric blog.