Technological Advancements in the Manufacturing World

Technological innovation marches forward with the latest advancements in the manufacturing world. These innovations change the ways manufacturers produce, develop, and maintain factories and supply chains for benefits felt in every industry.

With innovations that even affect healthcare solutions, these technological advancements are reshaping manufacturing as a whole. From self-sustaining machinery to energy-efficient systems, this new tech is helping protect the manufacturing industry from profit losses as the world faces a difficult economy.

Image Source: Pexels

Here, we will explore five essential innovations in the manufacturing world and the benefits they are bringing to the industry.

1. Self-supporting Machines

Smart machinery is easing the production process. With machines that can scan, diagnose, and predict maintenance needs themselves, the potential for seamless manufacturing is greater than ever before.

Self-supporting machines rely on artificial intelligence and big data analytics tech in order to automate levels of machine maintenance. These machines collect and model data to create predictive maintenance recommendations. That means manufacturers can now maximize the ability of their tools by repairing and improving them long before a problem even occurs.

Data collection made possible by smart machines also allows for understanding of machine function, use, and performance, as well as user identification and product quality tracking. A self-supporting machine undergoes constant analysis and diagnosis of itself at every step of the manufacturing process. This saves manufacturers time, money, and manpower.

2. 3D Printing

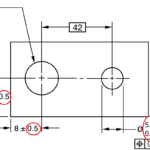

The state of manufacturing as a whole may be reshaped by 3D printing. This additive manufacturing process entails using a digital blueprint to compose a product from the bottom up. This method allows for a reduction in error, more efficient part design, and more diverse use of materials.

In PCB manufacturing, 3D printing is maximizing the potential of the industry by allowing prototype design and testing in-house. Formerly, manufacturers would have to rely on overseas developers and could face costly delays due to improperly constructed materials. Now, with 3D printing, a prototype can be designed and tested on the spot.

3D printing is even being used to manufacture biological materials such as organs in order to help save human lives. Dr. Anthony Atala of Boston Children’s Hospital in one instance was able to use such a process to manufacture a replacement bladder for a patient in need. To achieve this, his team modified a simple inkjet printer design to replicate biomaterial for safe transplantation.

With implications like this, the future of 3D printing in the manufacturing world spans industries and outcomes.

3. The Internet of Things

The Internet of Things (IoT), in the form of wearables and networks of connected smart devices, is reshaping the manufacturing world from the supply chain down. With the ability to analyze, scan, and predict supply chain routing and product quality, the Internet of Things is a foundational advancement in manufacturing, driving business in all industries.

In construction, this technology is being used to help develop and manufacture buildings with simulated models visible in augmented reality as well as through real-time data tracking. This enables manufacturers to compare the vision with the real world product for ideal results.

In wearable devices, IoT is transforming the consumer experience by communicating data with companies in real time. This in turn allows for better products as manufacturers are able to see consumer needs and fix problems as they occur.

4. 5G Wireless Technology

The emergence of the fifth generation of wireless technology has substantial meaning for the manufacturing world. In electronics, this makes for devices built for higher bandwidth, faster speeds, and greater connectivity.

With over 100 megabits-per-second data rates, 5G technology requires devices that respond as fast as the network will allow. As the abilities of our wireless networks improve, the trend in electronics manufacturing is moving towards cutting-edge, reliably connected devices.

5G has broad implications for IoT devices as well, with the ability for the enhanced network to report more data faster. As these technologies improve, so too will manufacturing speed for devices of all kinds with 5G wireless access.

5. Energy Efficiency

There is a growing world consensus on energy efficiency and sustainability. This is true in the manufacturing world as well. Advancements in manufacturing have seen the development of traditional energy systems towards efficiency improvements that are saving manufacturers on energy costs and making for a more sustainable world.

New compressor technology, for example, has revolutionized the gas turbine energy conversion system. Now, compressors are able to achieve more steady airflow, saving energy, and producing cleaner results for manufacturers and energy producers alike.

Similarly, developments in electric motor technology are creating more efficient machines that require less electricity generation. This has the potential to save manufacturers in expenditures while making for a cleaner world.

Conclusion

All in all, the advancements in manufacturing are leading to improved systems, enhanced connectivity, and more sustainable solutions. With the emergence of 5G, wearable technology on the Internet of Things is being both increased from the production side and used in the manufacturing process to innovate systems.

These tech advancements are all about data and communication. As these systems improve, manufacturing costs are likely to decrease. In turn, savings may potentially be passed down to the average consumer.