4 Technologies That Have Changed the Manufacturing Process

Manufacturing is at the core of any healthy economy. In fact, the U.S. manufacturing industry alone is worth more than $2.17 trillion, creating 12.3 million jobs in America in 2016.

Over the past few decades, manufacturing has been directly affected by most global trends, including the technological and digital transformations that have occurred in recent years. While these have caused some adverse impacts like the increase in the income gaps of populations, as well as the disappearance of traditional jobs due to mechanization and automation, it can’t be denied that these innovations have also brought about a lot of good to the industry. These four technologies, in particular, have influenced positive changes in the manufacturing process.

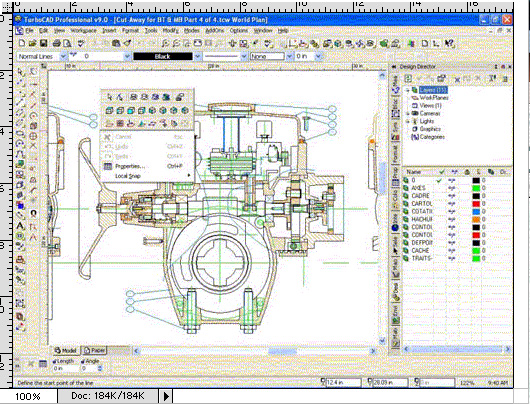

Computer-Aided Design

While computer-aided design or CAD is not top of mind when it comes to manufacturing-related technologies, it is especially important in creating 3D models prior to fabrication. With this step, manufacturers can get a full sense of the product, review all parts and features, and even check for possible faults.

Solidworks 3D CAD Software, for instance, allows 3D modeling with lifelike visualization and virtual testing. With built-in tools for thickness analysis, draft/undercut analysis, geometry checks, sheet metal checks, and more, Solidworks also allows manufacturers to check their designs against their cost targets, thus making the entire process more efficient.

Other benefits of using CAD in the manufacturing process include mechanical simulation and machine programming, which is especially useful for those involved in the production of complex or delicate parts.

Big Data and the Internet

Manufacturing companies can harness the power of big data and convert it into a strategic advantage. From marketing trends to customer behavior data, manufacturers can use this wealth of information to forecast future product demands and ride the waves of the biggest consumer trends.

The Internet, on the other hand, is especially helpful in automation and remote monitoring. For example, a damaged or defective machine can send data to another device, alerting the right personnel. In the future, these machine data can be collated and analyzed, which can help predict when machines should be repaired or replaced. This is a small application of the Internet in manufacturing, but can result in reduced downtime and costs.

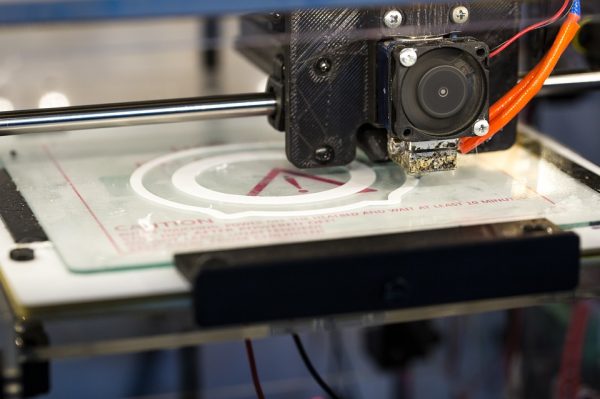

3D Printing

The idea of 3D printing can sound somewhat gimmicky or lofty—“I don’t need to buy something; I’ll just 3D print it”—but the technology itself has almost limitless applications, none more so in prototyping and manufacturing. In just a few years, the 3D printing has evolved from printing tiny cups to producing almost any kind of manufacturing component. Now, materials as varied as plastics, metals, concrete, and even human tissue are used in 3D printing.

Product customization can also be made easier with 3D printing. If research indicates a certain feature or design is more marketable, 3D printers can be programmed to fabricate the specific components, and product lines can change even while in midstream.

As 3D printing technology gets more mainstream and equipment more affordable, manufacturing costs can be drastically lowered in the near future.

Robotics

As early as the 1960s, when General Motors integrated robots in their car manufacturing plants, robots have been an integral part of the manufacturing landscape. Since then, robotics have been used more and more in manufacturing, from mixing ingredients to boxing items ready for shipping. Modern robots are also more sophisticated and can perform increasingly complex tasks that require precision.

However, as robots will never have the nuanced decision-making capabilities of the human mind, “cobotics” is now an emerging trend in manufacturing. Instead of completely doing away with human labor, robots are used as tools to help a worker finish a job faster and more efficiently.

The manufacturing industry has experienced quite a few ups and downs over the years, but one thing is for sure: technology is manufacturing forward, and it will continue to do so for the foreseeable future.