How to Avoid Common Mistakes Concerning Hydraulic Equipment

The Power of Hydraulics

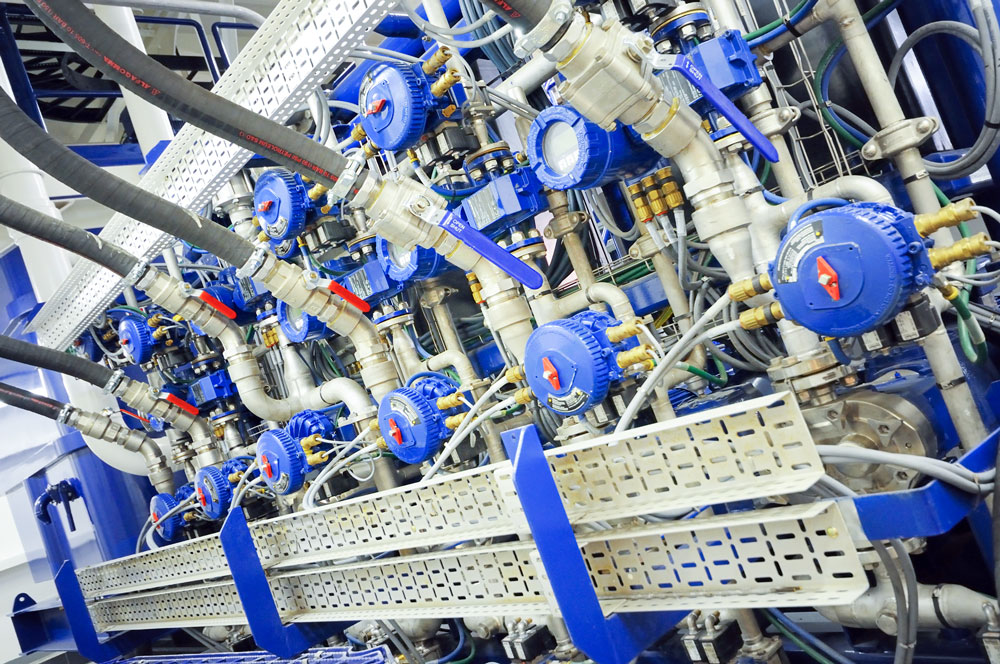

Hydraulics is a mechanical function which operates with the help of the application of liquid pressure. Therefore, if one pressurizes a container full of oil and extracts the resultant pressure to do some useful work, this would be a good example of hydraulics or hydraulic power. Typically in a hydraulic system there is a system of pumping liquid through different cylinders with the use of moving pistons. A hydraulic system makes life easier provided it runs smoothly and operates efficiently. It is of course fairly simple to know when a hydraulic system fails since then it will not do what it is expected to do, that is, transfer force. However, it may not be quite as simple to spot where all mistakes might have taken place in the hydraulic system. Since a hydraulic system is quite often very intricate and complex it may not be possible to spot the mistake and prevent it from causing a serious failure that has the capacity to harm. There are some very simple mistakes that one needs to watch out against in a hydraulic system. These mistakes have been advised by prominent hydraulics manufacturing company.

When to Change the Oil?

One must know when to change the oil. Oil is always changed depending upon the hours it has been used in service. There are only two occasions when one will have to change the oil. The first reason is when the base oil has degraded and the second is when the oil is depleted in quantity. There is no hard and fast rule for determining the time when the oil needs to be changed except with the help of a proper oil analysis. In one’s automobile too the oil is changed according to the manufacturer’s guideline which says that the oil has to be changed after say 10,000 km of driving with an over rider, change after say one year of use.

Use the Right Grade of Oil

The hydraulic system is all about the oil. If you are using the wrong grade of oil you are probably not getting the full benefit from the system. In the oil too it is its viscosity which is of the utmost significance. It is this viscosity that exercises control over the entire range of temperatures between the maximum and minimum limits that the system will operate safely. Therefore, once you know the operating temperature range of your hydraulic equipment you can select the right grade of oil that retains its viscosity in this range of temperatures.

The Need to Change Filters

The perfect and only time you need to change the filter is when it is unable to hold the dirt any longer. If you change all the filters as per a certain schedule then the chances are that you are either changing the filters too late or too early. Changing early means wastage of money while changing too late means that you are allowing dust and dirt to enter the delicate hydraulic system and the cost of a breakdown may be unaffordable. You can pick the right time if you were to keep a close monitor on the drop in pressure across the filter.

Do Not Run the System Hot

The hydraulic system is temperature sensitive. It cannot be used at a temperature that is higher than its limits. As the temperature rises the oil becomes less viscous and is no longer able to lubricate the system any longer. At this and higher temperatures hydraulic components are likely to sustain damage and this might lead to costly breakdown repairs.

Hydraulic pump manufacturers are efficient systems. However, one must abide by the guidelines in order that these systems run at peak efficiency at all times.