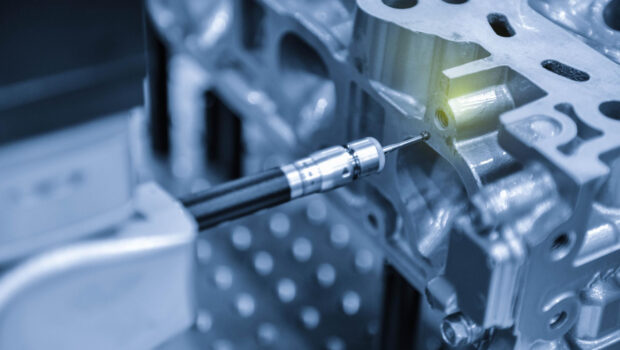

Injection Molding Machine Components And Their Functions

The injection molding process has improved to a higher level over the years. Plastic injection machines are manufactured in different designs and configurations, often made to suit the intended application. Many factors must be considered before a mold can be designed to function in a specific machine design. To select the correct machine mold design combination, its essential to consider the following factors:

- design of the proposed injection molded component;

- the properties of the raw molding material (resin);

- processing requirements in terms of component quality and production volume;

- economic viability.

The injection molding machine can be classified into three units:

- The machine base unit;

- the injection unit;

- The clamp unit.

The Machine Base Unit

The machine base unit is where the clamp and injection units are mounted. The machine base unit must have dimensional stability, accuracy, and strength. The injection molding process causes a high-stress

level in the unit, which has to be absorbed to prevent error or deformation in the finished product.

Modern machine base units are mostly fabricated from steel or other heavyweight materials. Due to the easy manufacturing process, the machine can be designed and modified to meet specific requirements. The base units are where the hydraulic oil storage tanks are kept.

The Injection Unit

The primary function of the machine injection unit is:

- melting and preparation of the polymeric resin;

- pressurizing and feeding the molten plastic to the mold under regulated conditions.

Injection units are based on two different designs of the system, namely, the plunger and the reciprocating screw designs. The reciprocating screw design is the most commonly used on modern plastic injection machines.

The function of the injection unit is to draw solid granules of resins into the screw flights as the screw is rotated using a screw drive motor. The resin is fed into the barrel, where it is heated. The screw helps in distributing molten plastic into the mold. This process is known as plasticizing.

The Clamp Unit

The mold must be securely clamped together for the molten resin to flow into the mold seamlessly under controlled pressure. When the mold is not securely clamped, it will result in the mold being forcefully opened, causing a flash on the split line. Apart from providing clamping force for the mold, the clamping unit is used to open and close the mold and sometimes to eject the product from the mold when required.

Injection molding machines can be powered hydraulically or electrically, but some machines are operated mechanically. Although the clamping force is generated hydraulically, it’s still transmitted mechanically to the mold through the moving platen. The two main clamping system designs include the direct hydraulic and toggle lock clamping system.

The hydraulic clamping system is powered with hydraulic force on the ram piston installed on the machine’s moving platen.

The toggle lock clamping system- the toggle assembly arms and linkages is controlled by the hydraulic actuation cylinder by means of falling the link assembly to open the moving platen and raising the assembly to close and lock the mold.

Cover Image by Freepik