Brief Overview of Calibration Standards – What They are & Why They’re Used

Did you know that everything you use in your everyday life has something to do with calibration standards? It’s true indeed. Everything from the water you drink to your smartphone and computer components is related to this concept in some way. When something is so commonly used, it begs more than one question.

For instance, what are calibration standards? Where are they used? Why are they used? If you want to find answers to these questions and learn more about this topic, all you have to do is scroll down.

What are calibration standards?

Not all devices are the same when it comes to their accuracy when measuring something – weight, temperature, the concentration of compounds, elements, and others. Experts often name the most accurate devices calibration standards and use them as their go-to source for accurate measurements.

These devices are used to verify the performance of all other devices that are not as accurate or have lost some of their accuracy over time. How do you know which calibration standard to apply in a particular use case?

For instance, the rule of the thumb is that they should be at least four times more accurate than the device being calibrated. However, calibration standards have to adhere to stringent requirements in some instances. Such is the case with Plastic Polyvinyl Chloride PVC, which must comply with WEEE RoHS Requirements.

Calibration standard definition

If you are more interested in definitions than general explanations, here is the widely accepted one:

“A calibration standard is an internationally recognized value that is considered objectively accurate.”

Why are calibration standards important?

There is not one industry we can name that doesn’t use calibration standards to ensure the quality of products and safety of workers, customers, and clients. For instance, you have standards to check lead levels in gasoline and sulfur levels in petroleum in the petroleum industry.

Some companies even specialize in finding and acquiring the standards for other companies so that they can stay compliant with the laws and regulations but also ensure the quality of their products.

The calibration is, in fact, the only thing that defines the accuracy and quality of one device’s or test’s measurements. It’s crucial to maintain the calibration of equipment because most devices tend to deteriorate and lose the ability to measure as accurately as they did before.

Thanks to calibration standards, we can calibrate these devices again and maintain the calibration as an ongoing process to ensure the long-term accuracy of devices and various equipment. Taking measurement uncertainty out of the equation is impossible. However, we can minimize it – we can control errors and consistently keep measurements as accurate as possible.

To sum up, calibration stands are essential because:

- They make collaboration between companies easier;

- They help ensure purity and quality of certain products;

- They help companies uphold the highest safety standards;

- They help us preserve the environment.

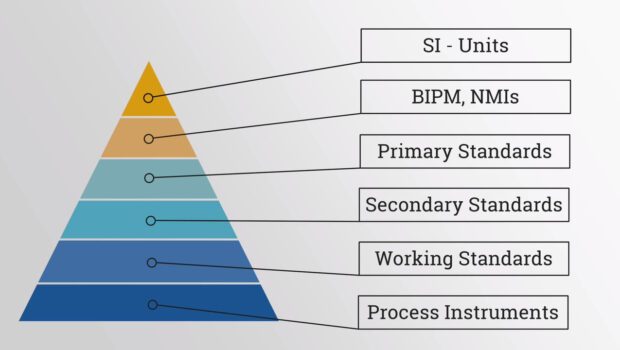

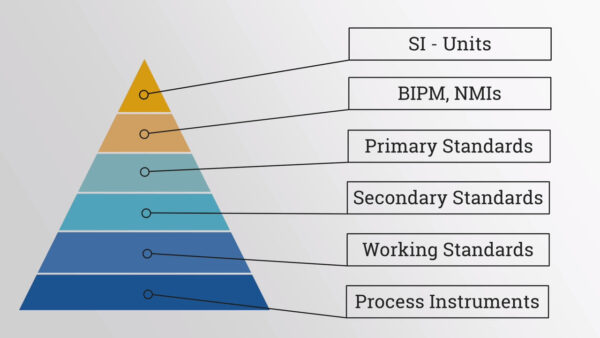

What are National Metrology Institutes?

National Metrology Institutes are where you can find the calibration standards. These are laboratories that specialize in calibration. Most of them are called NMIs, but there are also labs with unique names. These labs perform accurate calibrations and often form networks within one country.

Each one of these labs has to be certified, and the certification applies to three major aspects of calibration labs’ operations – quality, accuracy, and processes. These labs are often accredited by qualified organizations. While we are at NMIs, you should know that they all accept the International System of Units or SI.

SI outlines the set of globally accepted values, including the candela, second, meter, ampere, kilogram, kelvin, and mole.

A few examples of calibration standards

The best way to understand why calibration standards are crucial is to look at how they work in practice. For instance, manufacturers of kitchen appliances need to comply with several standards, including the temperature at which food is cooked. Without calibration standards, we would risk several food safety issues, potentially making many people ill or facing legal action.

In the petroleum and oil industries, calibration standards ensure matrix uniformity of crude and residual oils, including synthetic fuels.

Lastly, they play a vital role in the IoT sector. Given the sheer number of sensors measuring all kinds of parameters, calibration standards ensure that all these sensors collect and forward reliable information.

The calibration standards continue to change to answer the latest requirements as presented by new laws and regulations. They are important to keep us safe and prevent the pollution of the environment we live in.