Learn more about High Precision LVDT

High Precision Linear Variable Differential Transformer

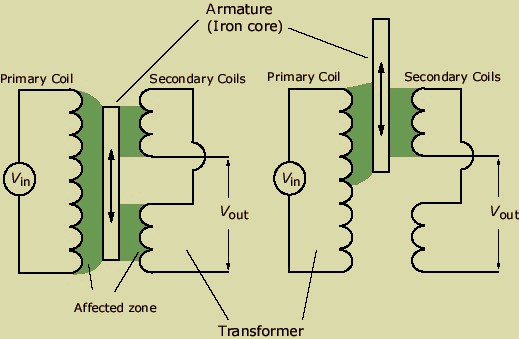

LVDTs are a kind of dual induction machinery and are primarily a sensor with continuous movement of a ferromagnetic armature inside a transformer. The transformer contains one primary coil associated with two secondary coils. The electromagnetically induced device has high levels of accuracy and is a reliable method for the measurement of linear distance.

General Key Introductory Facts About LVDT

LVDTsare primarily used as position-to-electrical sensors and an AC current with constant amplitude is usedas the input. The input supply produces an external signal as an output, which is directly proportional to the displacement or position of a non-static electromagnetic core. The attractiveness of LVDTs are for measuring displacements as no mechanical contact is present between the sensing elements. This makes them suitable due to the absence of unnecessary frictional forces that might lead to large scale wear and tear in the elements. The lack of friction also provides an additional advantage in that there is no distortion of the readings.

The robustness of the electromagnetic sensors is measured in terms of no mechanical connections, which might have caused fatigue failures. Also, the high-end industrial use of the device, due to the lack of mechanical connections, means that the minimum resolution of the electromagnetic sensor is based upon the noise thatis present in signal conditioning, as well as data acquisition systems. This allows for pinpoint high resolutions to be achieved easily from this device and thus increases its precision.

However, because the sensor relies on the lack of contact between the core and the body, the transverse motion must be minimized to avoid internal rubbing. Another possible drawback to the use of LVDTs is that the sensor’s operating range is limited by the size of the sensor itself since the core must remain within the coils for the system to operate correctly.

Working Of High Precision LVDTs

The working of the electromagnetic sensor is based on the movement of the magnetic core in a linear fashion inside the transformer’s cylindrical structure. The primary coiling gets its excitation current froman external alternating current (AC voltage) supply with constant voltage. This leads to a coupling effect in the 2 secondary coils which are wound in a cylindrical form and are present on both sides of the primary coil.

The winding pattern of secondary coils in opposite directions gives rise to secondary voltages.

Relationship Between The Orientation Of The Secondary Coils And The Magnetic Core For Measurement Of Displacement

The opposite direction of the secondary coil windings and the positioning of the core at the transformer’s magnetic center lead to the cancelation of two electromagnetic flux. Thus no voltage is measured at the output. But with the movement of the magnetic core away from the central position, a great amount of magnetic flux is induced, which has a coupling effect. The coupling effect of the magnetic flux in the 2 two secondary coils is unequal, which leads to the development of a voltage differential within the transformer circuit. Thus it is evident that when the magnetic core is present within the LVDTs’ operating range, there is a linear relationship between the amount of output voltage and the linear as well as rotatory displacement of the magnetic core.

Also, the magnetic core is threaded for facilitating an attachment to a nonferromagnetic rod.

Applications Of High Precision LVDTs

- The instrument is used in modern machine-tools and avionics, as well as in robotics and it also hasdiverse usage in computerized manufacturing. The sensor element gained immense popularity in the process control industry after World War II, because of its role in aircraft manufacturing and control systems, along with torpedoesand other weapon systems.

- The device has potential applications in civil infrastructure sensing systems and algorithm designing.

- LVDTs are used as position and motion sensors, as well as for high-end use as variable-reluctance transducers for relative motion.

- Diverse use in power turbines, nuclear reactors, hydraulics as well as in automation machinery and satellites.

Limitations Of High Precision LVDTs

- The problem of longer strokes in LVDTs can lead to connecting rod “sag”, which occurs because of the weight of the core.

- Large energy expenditure due to low resistivity and generation of eddy currents, which result in poor performance of the LVDT.

- High sensitivity to external magnetic fields and there are problems with some nonmagnetic stainless steels, which exhibit permanent magnetization.

- The use of non-metallic, non-conductive materials like composites and plastics leads to greater coefficients of expansion as compared to metals. Thus it leads to the development of output zero/offset shifts with temperature.

- LVDTs have a limited operating range of the sensor due to the size of the sensor.

- LVDTs have a complex circuit along with extremely high costs.

- The problem of phase shift between excitation and output voltage in case of AC LVDTs.

- The misalignments between core and bore-liner in the case of short strokes greatly affects the precision.

How To Overcome The Limitations And Challenges While Using High Precision LVDTs

- The rod sag in the long stroke in LVDTs can be minimized by reducing the overall weight of the magnetic core, while the core and body connectivity must be enhanced for maximum flexibility and for self-lubricating of the magnetic core.

- For optimum energy expenditure, it is important to avoid using low resistivity metals like brass and aluminum.

- To avoid permanent magnetization it is important to demagnetize the magnetic component before attachment with the core element.

- To avoid offset shifts and greater coefficients of expansion, the use of magnetic components is beneficial rather than using non-metallic composites, but to maintain an optimum temperature within the permissible range, a hydraulic oil cooler radiator can be used to avoid unnecessary heating.

- The miniature size of LVDTs can be conjugated with specialized mounting blocks for enhancing performance by allowing axial adjustment of the LVDT for the zero position.

- The complex circuit problem can be minimized by advanced automation of the signals by sinusoidal waveform signals and also costs can be minimized by cost-effective signal conditioning and use of digital linearity correction along with digital serialization and power management. It is important to use on and off circuits that can be self-monitored by systems.

- The misalignment of the core can be avoided by a rigid fitting of the core magnetic element and the use of core interchangeability interlinked with highly efficient output signals.

FAQs

Q1: What is a Linear Displacement Measurement?

A: Linear displacement measurement refers to determining the movement of an object in 1 direction along a single axis and the output signal of LVDT represents the total distance that the object moved from the initial reference position.

Q2: What is the benefit of using a high precision LVDT?

A: It has a high level of robustness due to the absence of wear and tear due to non-frictional forces and no contact between the core magnet and body. Also due to the coupling of magnetic flux, it has infinite resolution.

Thus it achieves the highest precision in the measurement of the smallest fraction of movements when used with suitable signal conditioning hardware.

Q3: What is the best signal conditioning for LVDTs?

A: SCXI is considered as the best signal conditioning platform. It is a PC-based data acquisition (DAQ) system and helps to determine LVDT output that lacks polarity. Also it determines a combined set of information about the phase of the output associated with the magnitude of the output signal in a sinusoidal wave function.

Q4: What are the challenges to achieve high-efficiency with LVDTs?

A: Rod sag on long stokes, large energy expenditure, sensitivity to external magnetic forces, greater coefficient of expansion for metals in high temperatures, high cost, and complex circuits along with misalignment of the core element.

Q5: How can challenges with LVDTs be overcome?

A: Self-lubrication and reduction in the weight of the core magnetic element, use of high resistivity metals, demagnetization of objects which are to be attached with the core after finishing the process, maintenance of optimally low temperatures, size management with the use of adjuster blocks to maximize performance along with cost-effectiveness and rigid fitting of the core element.