The World Of Devices: Comparing Piezoelectric, Electrostatic And Electromagnetic

As physical and digital infrastructures become more complex, evolving sensor technologies are critical to proactively detect potential problems and suggest specific solutions. The challenge is, sensor solutions aren’t uniform.

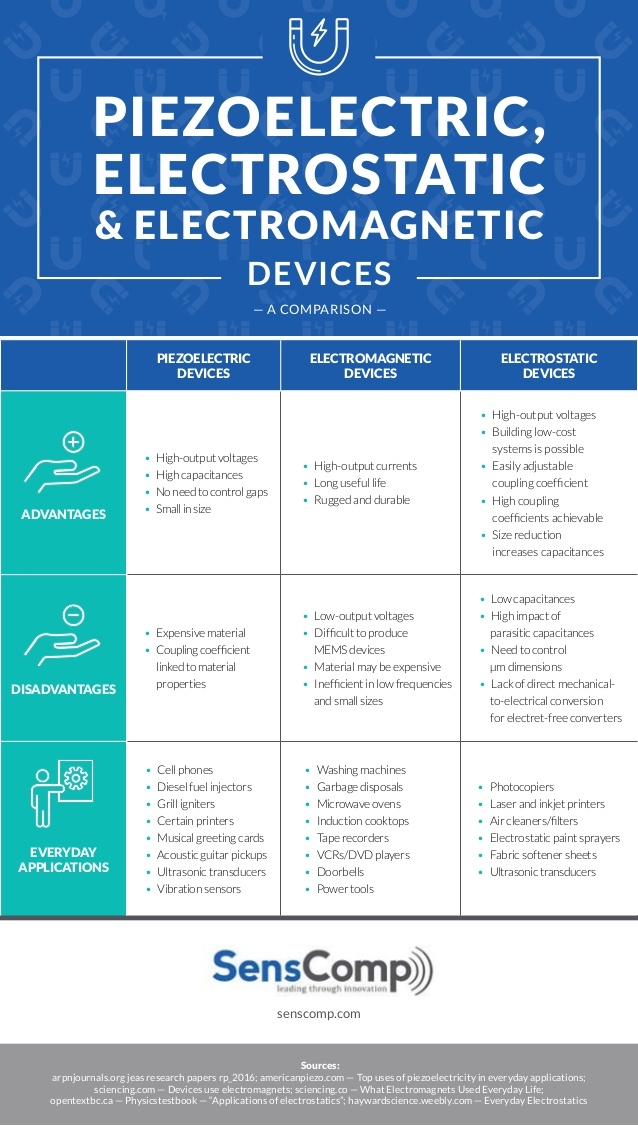

Piezoelectric, electromagnetic and electrostatic offerings all have distinct benefits and drawbacks. Multiple factors influence the best-fit system for current application — from the sensor environment to the speed, precision and reliability of reporting.

To overcome this device differential and ensure the sensor system you select provides actionable, accurate data output, it’s essential to understand where each of these sensor types excels — and where their efficacy ebbs.

Here’s what you need to know about piezoelectric, electromagnetic and electrostatic systems at scale.

Tackling the Sensor Trifecta

Electromagnetic sensors are known for their reliability — the manipulation of magnetic and electric fields to deliver strong, reliable effects has been well-researched. Electromagnetic solutions show significant durability when compared to other sensor types.

Piezoelectric options confer the benefit of small-scale design for applications that require high output voltages and capacities.

Emerging electrostatic options, meanwhile, offer unique benefits — including the ability to build low-cost systems with high voltages and high coupling coefficients.

Let’s tackle the sensor trifecta by exploring each type in more detail:

- Electromagnetic options: Electromagnets leverage the interaction between electric current and magnetic substances to produce field changes in either direction. For example, by wrapping a length of wire around ferrous metal and inducing current, a magnetic field can be created. Similarly, the presence of a strong magnetic field can generate electric current in the wire.

The biggest benefit of electromagnetic sensors is their durability. Unless significant damage is done directly to the sensor, the desired electric/magnetic action is consistent and reliable. Where electromagnetic options fall short, however, is in their cost and voltage: The materials required for electromagnets are expensive and their electric voltage is low-output.

- Piezoelectric solutions: Piezoelectric options leverage electrical potential of crystalline structures under stress. When mechanical stress is applied to crystals, the resulting deformation causes a rebalancing of electric charge, with one side of the crystal developing a positive charge and the other side developing a negative charge. The effect also works in the opposite direction. If a current is applied to piezoelectric crystals, it will cause the crystal to deform.

Piezoelectric solutions are often used in small-scale sensor applications that require a high degree of accuracy. However, they are expensive to produce. Tier coupling coefficient is directly tied to their material properties — differing crystal types deliver significantly different results.

- Electrostatic systems: Electrostatic systems depend on potential energy contained in a parallel plate capacitor. As capacitor plates are brought closer, the amount of potential energy required to separate them increases. When moved apart, the capacitance of the entire system decreases, resulting in a usable voltage increase.

Electrostatic solutions provide high-output voltages and are less costly to build than electromagnetic or piezoelectric options, but have lower overall capacitances.

Identifying Ideal Use Cases

No sensor type is ideal for all applications. While electromagnetic devices are inefficient in low frequencies and small sizes, piezoelectric sensors are expensive. Their coupling coefficient is inextricably linked to their material properties. Electrostatic options, meanwhile, do not provide direct mechanical-to-electrical conversion. For optimal performance, it is critical to control sensor specifications to micrometer dimensions

As a result, it is essential to identify the ideal use case for each device type. For example, piezoelectric systems excel in small-scale applications such as cellphones and vibration sensors. On the other hand, electromagnetic devices are often found in large appliances such as washing machines or induction cooktops. Electrostatic solutions are common in photocopiers and laser printers, but are also finding broader use as ultrasonic transducers.

Unpacking Electrostatic Potential

While electromagnetic solutions are familiar and piezoelectric systems can be finely tuned to improve results in scale applications, electrostatic offerings remain largely unknown. In part, this stems from their relative age. Recent advances in flexible membrane reliability and conductivity are responsible for the uptake of ultrasonic, electrostatic transducers for multiple applications. Thus, electrostatic sensors are often overlooked in favor of more well-known systems — even if existing applications fall short in specific areas.

Consider a recent study. While the paper found that for mid-range uses the high biasing voltages required by electrostatic systems made piezoelectric options the best choice, the researchers also discovered that electrostatic devices outperformed their piezoelectric counterparts under low- and high-mechanical acceleration. In each case, electrostatic systems delivered significantly greater power output.

As a result, electrostatic sensors are now seeing significant uptake across industries such as agriculture, robotics, materials handling, mobile equipment management and water treatment. Consider the case of a water treatment plant looking to accurately monitor and record the volume of water in a holding tank.

Piezoelectric and ultrasonic electrostatic sensors could be used to determine the water level and send a signal when it falls below a specific threshold. Given the reduced energy loss incurred by electrostatic systems in low-acceleration environments, however, these devices are the ideal choice for long-term, reliable data gathering and reporting.

Sensors and Sensibility

The right device makes all the difference in practical sensor deployment.

Although electromagnetic devices remain rugged and durable, they are costly and cumbersome — ideal for large-scale applications. Piezoelectric sensors deliver precise performance at price, making them a great fit for small-scale devices, while emerging electrostatic options provide high output voltages at small sizes. With precise calibration, electrostatic sensors are ideal for ultrasonic applications at scale.

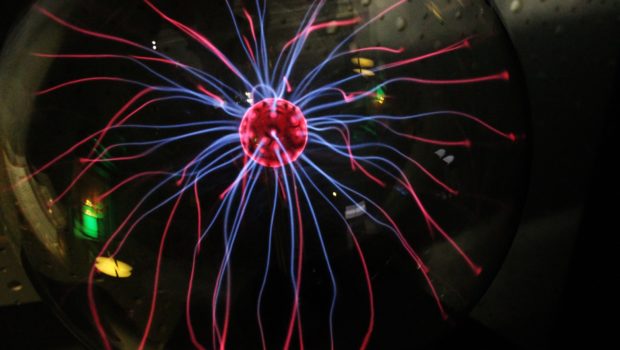

Image by Asimina Nteliou from Pixabay

Author bio: Margaret Bezerko is President of SensComp, a world leader in ultrasonic sensors. She has 18 years of experience in the industry and currently focuses on leading the company in second stage growth.