ERP modules for wholesalers

Wholesalers and distributors play a key role in the even distribution system, thus, this forms a bridge between the manufacturers and the retailers. Even though this group is very essential for the overall supply chain, it is more often overlooked by the software vendors.

Today, there are thousands of software solutions that meet the needs of the manufacturers and the retailers, and only few solutions that cater the needs of the wholesale and distribution industry.

The business of Wholesalers and Distributors

The mediators of the supply chain between the manufacturers and retailers are the wholesalers and distributors. Furthermore, retailers order required products in bulks from wholesalers who then purchase those from other suppliers.

The role of the middlemen is played by the distributors between the manufacturers and retailers by providing additional services such as adding value to the product, taking an active role in the sale and promotion of the product, and processing returns.

In the real world, there are times when wholesalers and distributors are not clear-cut of their statuses, and many times wholesalers will provide distribution services and vice versa. Therefore, many companies label themselves as “wholesale distributors”.

Manufacturing-Wholesalers-and-Distributors-Retail

There are 4 main components for Wholesalers and Distributors of every ERP

The needs of the wholesalers and distributors are not covered by The Odoo ERP for manufacturing or retail majority of the time. Deep involvement in some areas is required that are not present in the manufacturing and retail business. Every ERP for wholesalers and distributors should provide these 4 main business areas:

Distribution process management

Supply chain management

Retail and e-commerce

Back-office operations

Wholesalers and distributors ERP should be consisted of: business platform capabilities, location-specific functionalities, as well as different software delivery modules.

Distribution Process Management

There are six main areas of the Distribution Process Management:

1. Distribution requirement planning (DRP) manages the wholesalers and distributors specific demands, it is considered the planning engine, similar to the manufacturing requirement planning (MRP).

2. The logging entry and tracking of customer orders status is handled by the Sales Management. The management of complicated pricing deals, inventory allocation procedures and support for return and refund policy.

3. Purchasing management (procurement management) automates the purchasing of the raw industrial materials, semi-finished and finished goods, and locate suppliers’ commitment as per their contract terms.

4. Quality Management, also known as Quality Control, refers to a set of actions taken by the organization to make sure that it creates and delivers high-quality products as per its demand and expectations. Organizations must commit to the local, national and international rules and regulations, any sort of violation will not be accepted. But some of them create and use internal requirements for quality control.

5. Customer Relationship Management (CRM) covers a wide range of functionalities including: campaign and leads management, sales force automation, customer service and support, etc.

Barcoding and radio-frequency identification (RFID) are very important capabilities of the ERP for wholesalers and distributors. Products must be labeled and packed with barcodes for efficient movement across the supply chain. The movement if the goods is improved when RFID tags are applied and supported in the movement process.

Supply Chain Management (SCM)

The process by which all business operations between suppliers, manufacturers, wholesalers, distributors, retailers and customers are done is known as Supply Chain Management (SCM). Moreover, for deeper SCM functionalities than the regular ERP systems, an ERP for wholesalers and retailers should be used. This system of ERP will monitor and should cover the following four Supply chain areas:

1. Warehouse management system (WMS) supports the day-to-day operations in a warehouse. WMS system enables centralized management of tasks such as: tracking inventory levels and stock locations, optimization of picking, putting away, replenishment functions, etc. The collaboration of operations which are system-directed, backed up by real-time, paperless and interactive information systems will provide warehouse management and personnel with the tools to guide, maintain, record and report on distribution operations.

WMS-Wholesalers-and-Distributors-ERP

2. Transportation management system (TMS) allows organizations to create profiles for all contracts, associated carriers, and trade lanes for intermodal and multi-leg moves. It is essential for these systems to support and provide regional as well as international transportation movements.

3. Global trade management (GTM) aids trading partners to engage in a technology-based dialogue to cooperate in storing, moving, transporting and settling accounts across borders. Product data will be tracked by this system at all times and will manage compliance of products to enable cross-border business operations without any sort of inconveniences.

4. Supplier relationship management (SRM) makes sure companies have access for communication and collaboration with dealers, partners and suppliers regarding products, services, compliance and logistics.

Retail and E-commerce

Soft wares such as Retail and e-commerce ensures that the sale of products and services to business and directly to customers. It includes the following key areas:

1. Internet based multipurpose commerce makes virtual shopping experience for both business-to-business (B2B) and business-to-customer (B2C) customers. Moreover, It provides the opportunity to search, compare, and purchase goods online.

2. Retail and Point-of-Sale (POS) software records, tracks, analyze data and transactions at retail locations (online or conventional stores).

POS-Wholesalers-and-Distributors-ERP

Back-office Operations

Even though, this is a broader category of systems that are necessary for management and running an organization, this 3 areas are extremely important for any sort of wholesale and Distribution Company to run their back-end operations:

Financials applications manage the financial resources of the organization. This include accounting and financial reporting, budgeting, collection of accounts receivables, and risk management. Functional components include: general ledger, accounts payable, fixed assets, cist accounting, cash management, accounts receivable and financial reporting.

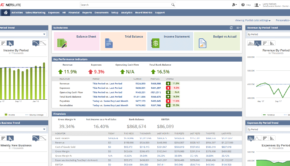

Financials-Wholesalers-and-Distributors-ERP

The importance of Contract, rebate, and chargeback processing is immense for the wholesale and distribution companies that is why it is listed separately. Therefore, Wholesalers and distributors are often required to manage complicated contracting situations for complicated networks of buyers and sellers. The contract management and analysis functionality will also need to be strongly linked to the rebate and chargeback processing requirements.

Human resources (HR) manages the personnel-related tasks. It includes the following functionalities: personnel management, benefit management, payroll management, employee self-service, health and safety.