Engineering 101: Level Switches Explained

Level switches work in a system with level sensors, and are used to detect the level of liquids or fluidised solids within a container. Level sensors can be set up to monitor continuous values (measuring the exact level of a substance within a specified range), or a single point, to identify when the volume of a substance meets, exceeds or drops below a certain level. The level sensor(s) send a signal to the level switch, to either stop the incoming flow of liquid or restart it.

Level sensors are compatible with slurries, grains, oils and powders – any substance that would typically create a horizontal surface (rather than a peak) that can be accurately measured. They are very different from well pump pressure switch, that mostly come into action only when a pressure difference is by the valve.

When are level switches usually used?

You can find level switches in a number of applications, from industrial and commercial processes to everyday items in the home. These switches are typically responsible for controlling pumps, activating alarms or to trigger an action in another device.

A toilet cistern is a simple example. Activating the flush drains the tank, which is then refilled by the inlet. The ballcock, acting as a float switch, ends the flow once the water reaches the appropriate level.

Premises with a domestic or commercial fuel tank usually use a level switch to monitor the internal quantity. If the surface of the oil suddenly drops below a certain point, an alarm is triggered that warns the owners of a possible leak or theft.

Level switches can be found in household appliances, automotive applications, heating and cooling units and pump systems.

Types of level sensors

There are numerous types of level sensor and switch combinations, which get increasingly complex as the application requirements increase. Here are four of the most basic types of level sensors to get an idea about how they function.

Lasers

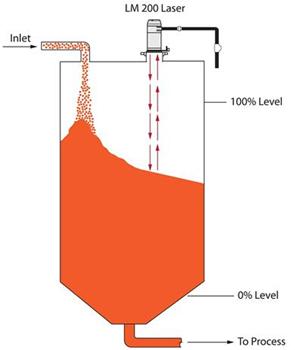

Laser sensors are low-cost and suitable for most continuous-monitoring applications, as long as the substance you are monitoring is opaque. They work by transmitting a pulse of light from the top of the tank downwards into the material below. A tim

ing component measures how long it takes for the beam to be reflected back from the surface and uses that to calculate the distance between them.

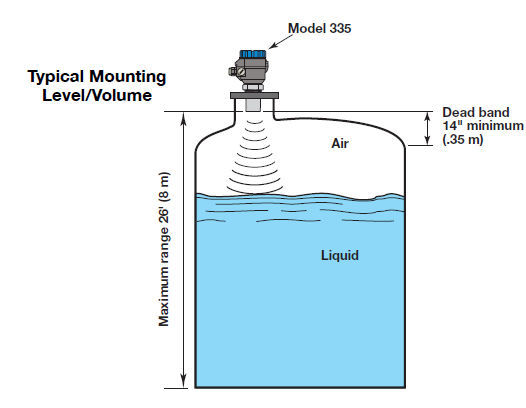

Ultrasonic

Ultrasonic sensors work in a similar way to lasers, except they rely on high-frequency sound waves instead of a beam of light. However, these components are more susceptible to fluctuations within the container such as turbulence, heat and dust or foam. For this reason, it’s important to think carefully about their positioning.

Vibrating

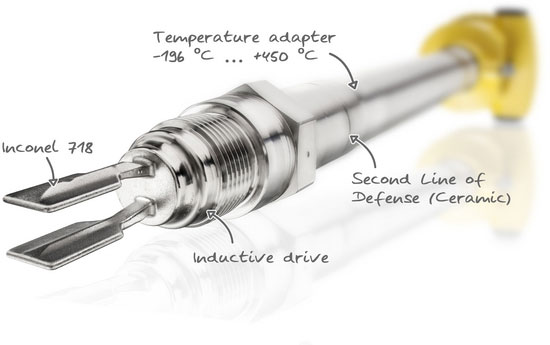

Bulk powders and grains can be measured using a tuning fork, which relies on tiny vibrations to confirm that the substance has not reached a certain point. The fork is affixed to a sensor which relays the information back into the circuit.

Float

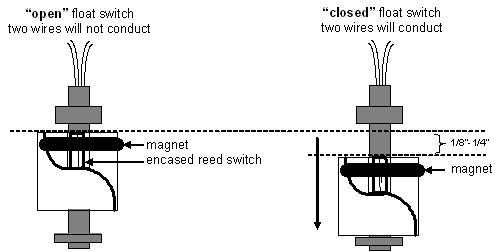

Liquid level monitoring is often done with magnetically-actuated float sensors. These components have a magnet permanently sealed inside a float, which is positioned to connect (or disconnect) with a microswitch if the level of the liquid rises or drops past a certain point.

Mechanical float switches are also commonly used in liquids, due to their simple design and reliable results. In a mechanical level switch, a buoyant component rises and falls on the surface of the liquid, but instead of using a magnet to close a circuit, it physically moves a connected lever or flap – just like in a cistern.

What to know before installing a level switch

There are several things to consider when choosing the most appropriate level switch for your application.

The most important issue is to pay attention to the substance that you will be monitoring. As explained above, although fluidised solids and liquids may behave in similar ways, their properties will have different effects on certain types of sensor and switch. The corrosiveness, temperature, opacity and density will also have an impact on the type and material of the most reliable, durable and cost-effective sensor.

The most useful thing about level switches is the versatility in their simplicity. Once you understand the basics of how they work, you can begin to combine them into complex systems to satisfy the needs of almost any level-monitoring application.