7 Mistakes to Avoid While Using CNC Lathes

According to dictionary.com, automation refers to the technique, method, or system of operating or controlling a process by highly automatic means, as by electronic devices, reducing human intervention to a minimum.

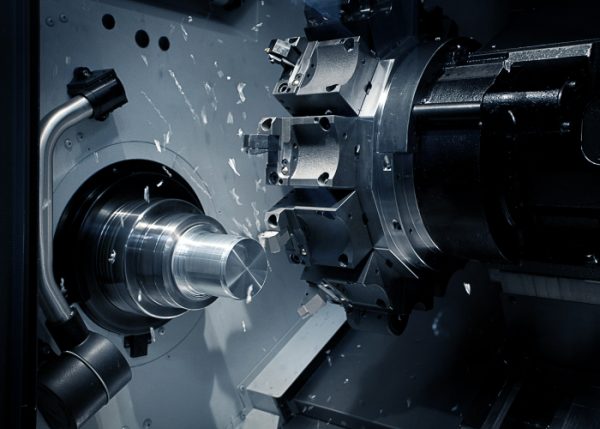

Which is honestly a blessing, especially in the machining industry? Computer-controlled machines have reduced human efforts by half, providing us with precision parts in a much lesser time-slot. When you need a small screw or an airplane wing, in dozens or millions, CNC machining has made everything possible.

Similar goes in the world of lathes. The introduction of CNC lathes has been nothing short of a blessing for the machine shops providing high precision parts. But, even with the computer in place, there is a host of instructions that only their manual counterparts can set (for now, we don’t know what lies in the future, do we?). And while machines (rather computers) may make mistakes, this field is undeniably ruled by humans.

So, here’s the list of most common mistakes even an expert CNC’er can make while working with a CNC lathe:

1. Cutting tool is set to the wrong height

Definitely an apprentice mistake, but sometimes even a pro can misjudge a cutting tool placement.

On a metal working lathe, a cutting tool should always be placed on the right of the central part of the chuck. The tool should neither be placed too high nor too low. It ensures proper cutting and thus, a properly fabricated machined part. In order to avoid heating up of the cutting tool tip during the process, you should always start slowly gradually increasing the speed.

2. Minimum knowledge of carriage movement

As they say, in order to get the thing done well, you need to get in the depth of it. As a CNC’er you should have some knowledge about every part and processes involved, if not all. And that includes the working of carriage and power feed handles, if you are working with CNC lathes. You should know how the carriage moves, where you can go wrong with it and how to correct it and aspects like that. To answer you, a carriage moves along the tracks, going to and fro from the chuck as the cross slides move to and fro from the center of the lathe.

3. Going too slow

Slow and steady wins the race. Well, not in the world of CNC lathes. You don’t have to be the tortoise here; it would cause more harm than help.

In fact, a slowed down feed rate can lead to a poor quality cutting. Not our goal. This is cause a slower RPM makes the cutting tool almost ineffective; it’s just rubbing against the material, generating unnecessary heat in the process. Not to forget all the tool-dulling it causes. All of this leads to uneven cuts, not the sharp and even cuts we require in producing precision parts.

4. Going too fast

If moving slow can’t help, going too fast throughout can’t help either. The trick is in using different feeds and speeds at different parts. This step is absolutely essential when you dealing with thread cutting. The chuck gets almost uncontrollable at higher speed, which will definitely hinder the thread cutting process.

5. A loose tailstock

While a tailstock isn’t the most important part of a CNC metal lathe, it’s still a part of it. So not paying attention to it can still cause imperfections in the metal parts.

Before you feed the chuck, make sure that the tailstock is properly locked down by screwing shut all the loose bolts (generally present on the tension lever or on the unit base).

6. Improper Maintenance

Improper maintenance or, in several cases, no maintenance at all is one major mistake a lot of CNC machine shops make. You need to understand that by ignoring regular inspection and maintenance processes, you are constantly putting both your valuable machines and resources in danger.

Just like every machine in general, CNC lathe machines should be cleaned rather frequently. Ensure that the coolant levels and airflow are not disrupted by anything. Any loose chip or debris should be cleaned from the machine.

7. Ignoring Safety

This is in continuation of the last common mistake. As an employer, promote a safe working environment. As resources, ensure your safety at every possible time. Be safe while working with a metal lathe or any other CNC machine in general. Keep your protection gear on, wear appropriate clothing and footwear.

Keep a small brush handy to remove any visible chip which can potentially cause damage. Never forget to wear your gloves, especially when you’re working with a cutting tool.

These are small steps, but these small steps can save your life.

Now when you are aware of the small but significant mistakes one is prone to make while using CNC lathes, just make sure you don’t!