Introduction

The ISO 9001 certification is an international quality control management system that is widely accepted as a benchmark for deliverance of consistent quality for a company. The ISO family of quality management systems ensure that your company is providing the customers with high quality goods that meets their needs and expectations. There are a lot of third party certification bodies available today but the ISO standard is still widely regarded as one of the most prestigious certification bodies in existence and millions of organisations are certified by this body.

How does getting the ISO certification help your organisation?

There are numerous benefits of getting certified by the ISO standard. It is a general representation that your company has the means to produce or render services and goods that are on a level playing field comparing on an international scale. The ISO standard also essentially helps build a faith among new investors that are maybe willing to invest in your company. And although the ISO 9001 standard isn’t really the line on which your company operates and the management systems are based on, it does provide with a good base on which the company’s management decisions and process control could be built on. It works even better for newer companies that have yet to make a big splash in the markets, thereby making it a good starting point for any company to consider getting an affiliation.

Here are a few additional benefits of certifying your organising your organisation with the ISO 9001 standard:

- Higher customer retention rate: The ISO 9001 standard is recognised all over the world as a measure of quality and as a result, there are a lot of people who recognise it. If your company’s products are labelled with the certification, then the customers will definitely revert back to your brand because they essentially know that your products are passed through thorough QC checks to ensure a consistent quality, compliant with the ISO standard guidelines.

- Trust building among investors: Investors are essentially the backbone of any company. Without proper funding, your company cannot keep up in the competitive marketspace. The ISO standard has a strict set of rules regarding investors that invokes trust building among them when they come forth to invest in your venture.

- Cuts down on R&D: The ISO standard has lots of pre-formatted documents and resources that your company can benefit. Most of them either focusing on employee training, resource management and product handling. Although there is no set bar for this and external involvement will definitely be required, it will at least provide as a base on which your company can base its work upon, so they have to start from scratch.

- Helps to improve decision making: One of the biggest USP’s of the ISO standard is that it relies on evidence based decision making. Meaning, that for every decision that you take, you need to have proper evidence to back up your decision. This not only helps in decision making but for the most part it improves overall efficiency by allocating resources to areas that will improve overall efficiency and performance, thereby saving precious resources by eliminating the possibility of implementing unreliable information, based on a trial and error method.

- Creates an environment for Improvement: Because the ISO system focuses so heavily on quality, it creates a continuous cycle which the company absorbs into its very core. This means that quality control for the company never remains the same and they constantly strive to find more efficient solutions to tackle the one provided by the ISO organisation, thereby looping the organisation in a state of constant improvement and innovation.

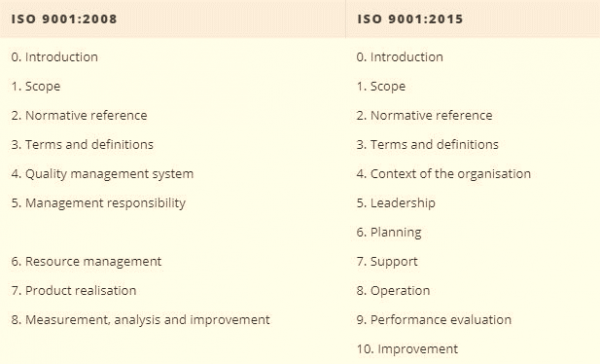

ISO 9001:2008 vs. ISO 9001:2015 standard

As with everything, the ISO standards too get revised on a periodic basis (usually 7 years) and the latest standard to follow suit is the ISO 9001:2015. This QMS revision brings a lot of new revisions to the ISO 9001:2008 standard and companies which are still using the older standard will have to transition by September, 2018. With that said, if the company hasn’t already certified itself with the pervious ISO standard, then it will be a good idea to get certified with the 2015 standard by default as 2018 is nearly here. Also companies still willing to get the 2008 certification might do so but they’ll need to confirm with the registrar whether the 2008 standard can still be granted.

With that said, let’s have a glimpse of what significant changes have been made with the 2015 revision.

- Compliance with Annex SL Directives: The ISO 9001:2015 standard’s compliance with the Annex SL Directives makes it easier to integrate with other quality management systems like ISO 14001, ISO 2000, ISO 22301, ISO 27001.

- Changes in structure: The ISO 2015 standard now has 7 core principles instead of 8 which the 2008 standard had but on the flip side, now it has 10 clauses instead of 8 compared to the previous version. However, the 6 mandatory procedures for the 2008 standard are now 6 mandatory documents. This was done on purpose because the initial intention was to introduce more liberty in documenting the quality management systems.

- New requirements: The ISO 9001:2015 standard introduces some new requirements and removes some older requirements in the following clauses:

- Clause 4: Context of the Organisation – deals in determining external and internal issues that can affect various management systems and also used as a factor to determine to stakeholder requirements that can directly affect business.

- Clause 6.1: Actions to address risk and opportunities – it encourages the organisation to include risk based thinking and deal in high risk scenario’s where there maybe opportunities that can directly impact the organisation.

For a more exhaustive explanation, see here and also read the full info here.

Other than that, there are few older requirements that have been removed like – Management Representative, Quality Manual and Preventive Actions.

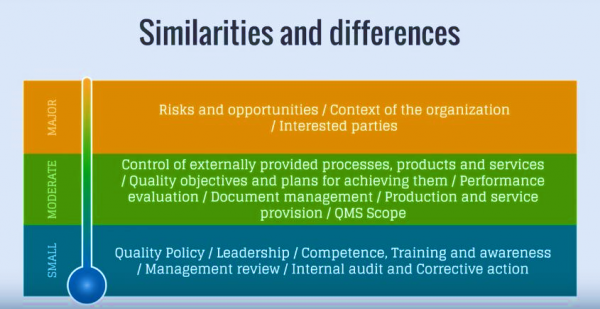

So in a nutshell, the significant changes brought about by the 2015 revision of the ISO are as follows:

- Introduction of the risk based thinking process for the organisation.

- More emphasis on close performance monitoring

- Better implementation for involvement of top management in QMS

- Enhancement of process approach and PDCA cycle

- Better integration with other management systems

- Decentralised system leading to spread of responsibilities throughout the organisation for QMS.

So how can your company achieve the ISO certification?

For newer organisations, getting the ISO certification might be a slightly bigger process as they sometimes won’t have necessary industry standard-know how about quality management systems that the ISO 9001 standard requires.

For this there is a step by step procedure by which their organisation can get the ISO 9001 certification. The process is outlined here. The certification processes comprises of 5 stages primarily:

- Preparation: This stage primarily comprises of preparing your company for the processes relating to the certification for the ISO QMS. If the organisation hasn’t had any QMS certification before, then it might be a good idea to get acquainted.

- Appointing a QMS Manager: This process also includes appointing a local Management Representative from inside the organisation who has sufficient authority to change the operational processes inside the organisation. He/she will be responsible for overseeing the process of implementing the ISO standard for the organisation.

- Training: The Management Representative needs to get trained for the process of the ISO transition. The individual will need to go through the forms and documents relating to the specific ISO 9001 version that the organisation will implement.

- Getting the management to agree: It is important that the entire organisation understands and supports the ISO QMS system. The Internal Representative will be responsible for explaining the pros and cons and the processes relating to the transition. After this is done, the second phase can begin.

- Documentation: This is usually the most difficult part in the whole process of implementing the ISO 9001 standard. Every organisation that implements the ISO 9001 standard has to have a manual that depicts their organisational practices and quality control standards but at the same time this has to comply with the guidelines and criteria’s of the ISO standard. Writing them at the beginning of the process is recommended because later down the line it could become a big hurdle.

There are 7 documents required by the ISO 9001:

- Quality Policy

- Procedures

- Scope of Quality Management System

- Process Map or Flowchart

- Quality Objectives

- Work Instructions

- Forms

- Implementation: After the documents are written, then it is finally time to implement the QMS system in place. The implementation phase requires you to follow your documents and put the necessary requirements into action. This may vary from company to company but it always complies with the ISO 9001 standard. The documents needs to be thoroughly explained to the department executives so they can monitor employee work patterns and assess that it meets the necessary requirements. Most of the employees will have to adapt to the new standard and quality control methods but with further training and practice, they’ll automatically get in the rhythm.

- Internal Audit: The internal audits are usually inspections performed within the organisation. The company can use these audits as a basis to evaluate themselves and see if they are complying with all the guidelines prescribed for getting the ISO 9001 certification. The audits are generally performed by individuals trained for setting up the ISO 9001 standard within the organisation. In most cases, the audits are performed by QMS Representatives within the organisation but companies can also issue 3rd party contractors to oversee the process. Audits can also be performed periodically after the company has been granted the ISO certification to see if everything is in order.

- Certification: This is the final step in getting the ISO certification. After you have completed the internal audit, you must appoint a Third-Party ISO 9001 Auditor to visit your company and perform the certification audit. Now there are a plethora of 3rd party companies that will give you the ISO certification but you must appoint someone who is associated with an official ISO accredited agency because there are some who aren’t. The certification audit is similar to the internal audits that your company performs but the auditor may perform close inspections of all of your departments, your ISO standard complying manuals and your workforce. He/she will determine if all of your workforce and your QMS manuals are complying with the ISO standard. If the checks comply with all the necessary regulations, then your company will be certified with the ISO affiliation however if there are any significant discrepancies, then you’ll have to correct them before getting the ISO certification.

Click here to read more on ISO 9001 Quality Management.

Conclusion

There are a lot of benefits that come with the ISO certification. Companies certified with the ISO 9001:2015 certification have the highest level of quality control right now. The ISO management systems maybe a bit expensive at first but in the long run, it pretty much pays for itself through good customer retention rate and investor trust building. However the ISO Certification isn’t a onetime process. The appointed registrar will perform routine checks periodically to ensure that the entire organisation is complying with the necessary guidelines prescribed by the ISO standard. The ISO certification can also be leveraged in marketing for medium to large sized organisations. So if your business doesn’t have a necessary QMS in place, make sure to get ISO certified and enjoy the long term benefits.