The Organic Revolution Fertilizes Nanography and 3D Printing

Hewlett Packard has been struggling to make waves for quite some time. If you followed the history of this company, you’ll know it has had its share of problems.

Blame ineffective CEOs, botched advertising campaigns, or poor insight into the market, but the company has had its struggled for some time now. Whatever may be said about HP, the company knows how to make a solid printer. Since 2014, the company has managed to create one of the top-selling B2 presses in the world with the Indigo 3D 10000. In 2017, the company is taking it to the next level with the Indigo 50000 model that is designed for high-coverage jobs on any paper type.

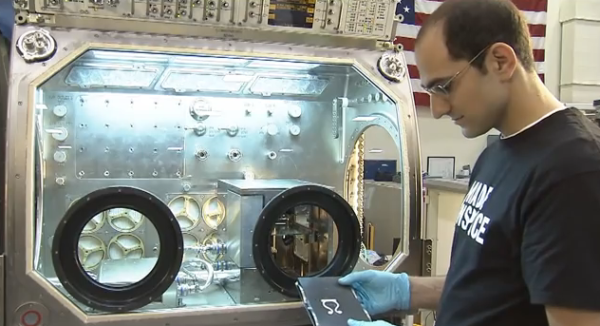

The First Replicator in Space

Bring up the topic of 3D printing, and most people will conjure images of printers capable of creating useful three-dimensional objects based on a set of instructions. Even NASA is now using 3D printers at the International Space Station. The first object made in space was a faceplate of the extruders casing. This is a huge development in the world of printing. As the technology improves, it’s likely to get smaller, more portable and available at your local electronics store.

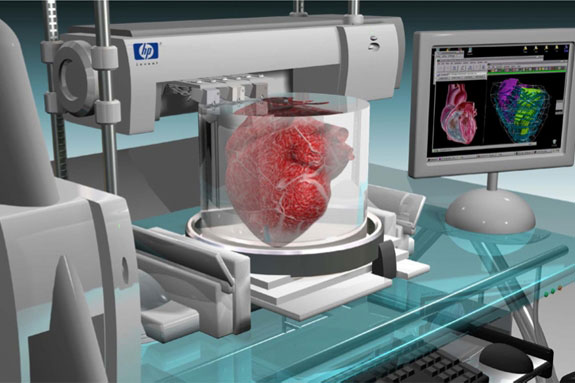

Manufacturing Living Organisms

As we get closer to a Star Trek fantasy where replicators are installed in every office and room, many people have lost sight of one important innovation that is set to save lives. Bioprinting offers a new technology that makes it possible to generate tissue that is designed specifically for an individual. As the cellular construction of the human body is complex, this technology has not had the speedy growth that mechanical 3D printing has enjoyed. Eventually, this technology could provide organs that are viable for use in a living human being.

How 3D Printers Work

3D printing offers an incredible technology that is finding usefulness in the military, commercial printing, medical centers and even the space station. The process works by taking a digital blueprint and then loading the desired materials into the printing device. As the blueprint is read, the printing mechanism moves in accordance with the blueprint. Clothing, toys, cases and other objects are easily manufactured using three-dimensional printing.

Printing With Living Cells

While you might think a bioprinter must use a completely separate process, the process is almost identical for creating organs as it is for creating a toy. Bioprinters need material to work too, and the materials they work with are living cells. These cells are then directed to follow a blueprint so that living tissue is created. The cells come from a human donor who needs a transplant. The cells are selected in such a way that they pair with similar cells and build the structures that are needed. It’s similar to getting a group of specialists together to complete a project. If you get the right people involved, they will use their skills to create your project and bring it to realization. Cells work in a similar manner and they have their own tiny blueprints that they follow as well.

The Future of Bioprinting

Eventually, it may be possible to create large structures like arms, legs and eyes. However, that sort of technology is still far in the future. Swansea University created a bioprinting process that can create newly printed bones that can be transplanted into the body where they begin to use and grow. Other applications include the development of new skin for people who have been badly burned, the creation of new blood vessels, and simple organs like bladders can be manufactured currently.

Research has even led to the development of human cartilage, which can be used to replace ears, noses and other body parts. The future of printing is expanding, and the ramifications are massive. And to think, it all started with the desire to make it easier to pass on knowledge to the masses through written media.