CNC Milling VS CNC Turning: How To Make the Right Choice

CNC machining is a manufacturing process that uses a computer program to produce engineering materials using a subtractive mechanism method. Unlike the traditional machining process where the machinist controls the lathes manually, the CNC machining process is controlled by a computer program. The software uses digital instructions to control the machine parts into cutting out parts from solid material or work-piece. The CNC machining process can create different shapes on various engineering materials like metals, wood, plastic, and sometimes glass.

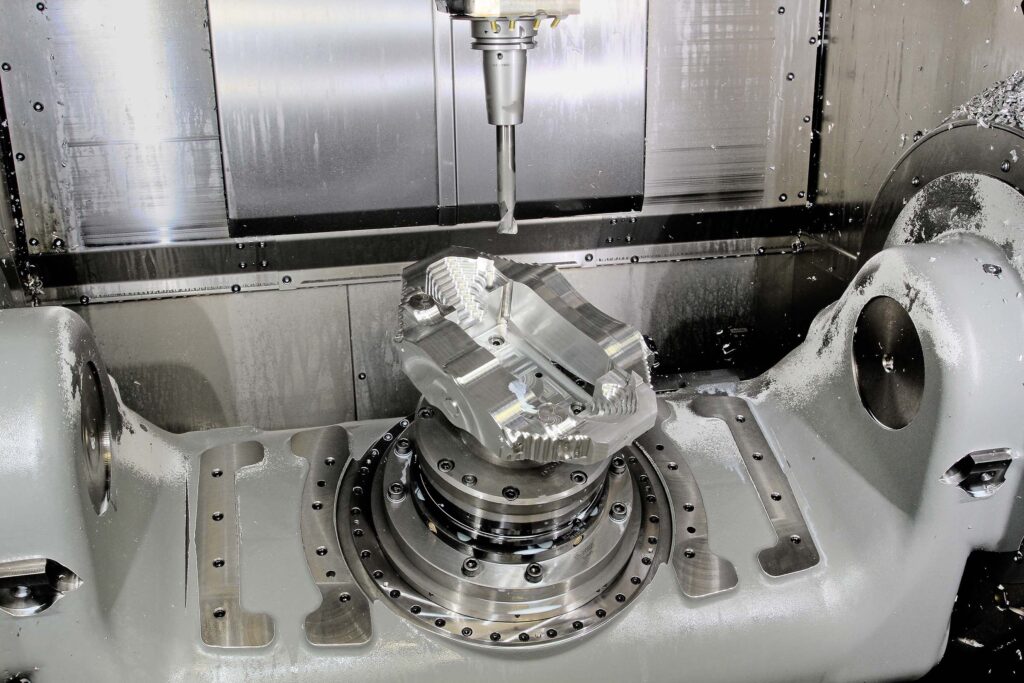

What Is CNC Milling

CNC machining milling is a machining process that uses computer instructions to rapidly rotate a cutting tool along three to five axes, cutting through into a stationary workpiece. It is one of the most common CNC machining services available for machinists to make various CNC machined parts. Since CNC milling is highly accurate, it is widely accepted in several industries in producing various items like prototypes for examination, single parts, multiple parts, and complete small runs.

4 Common Types of Milling Processes

- Face milling: This milling process involves the cutting tool positioned at an axis perpendicular to that of the flat surface work-piece that is to be machined.

- Plain/Slab milling: In this milling process, the cutting tool is placed at an axis parallel to the axis of the surface of the work-piece/material to be machined.

- Angular milling: As the name implies, the cutting tool’s axis is positioned at a specified angle to the surface of the material that is to be machined.

- Form milling: This process involves using a customized cutting tool formed to the shape required by the irregular surfaced work-piece, such as curved flat surfaces.

What Is CNC Turning?

CNC turning, just like the CNC milling, is a subtractive machining process that uses CNC, but unlike the CNC milling process, the cutting tool is held stationary while the workpiece is being fitted to a chuck and rotated while simultaneously being fed to the stationary cutting tool which cuts out the desired shape from the workpiece/material. It is a process used mostly in producing cylindrical parts.

Some primary types of turning operations are; taper turning, spherical generation, grooving, knurling, reaming, drilling, boring, facing, hard turning, and threading.

How to Choose Between CNC Milling and CNC Turning

The major difference between the CNC milling process and the CNC turning process is that CNC turning involves the rotation of the workpiece against a stationary cutting tool and is therefore used in the production of round, cylindrical, or conical parts. On the other hand, CNC milling involves rotating the cutting tool and driving it against a stationary workpiece. In turn, this makes CNC milling a good option when seeking to produce more complex parts. With this information, a customer can easily know which option to go for between a CNC milling service or a CNC turning service.

The CNC milling and CNC turning can be combined sequentially to produce more complex parts that require round surfaces and asymmetrical cuts or features.

Some Applications of CNC Milling and CNC Turning

Since CNC milling and CNC turning are both CNC machining processes, the industries in which the applications are required are the same, but they are used to produce different machine parts in these industries. Highlighted below are industries where CNC machining services are needed highlighting parts that involve CNC milling services in the production and the parts that require CNC turning services in their production.

Aerospace

The aviation industry is one of the most common industries that seek CNC machining services. The aircraft body and some other parts of the aircraft can only be achieved using a machining process. Below are some parts that require both CNC milling and CNC turning in aerospace;

CNC milled parts in aerospace: Airplane seat frames, illuminated aerospace control panels, hydraulic manifolds.

CNC turned parts in aerospace: Eccentric hollow shafts, joint connectors, fasteners, probes.

Automobile

It does not matter which kind of vehicle; machined parts are widely used in the buildup of automobiles. Below are some examples of CNC machined parts of automobiles;

CNC milled parts in automobiles: Car keys, engine cylinder block, valve retainers, bushings, exhaust parts, flywheels.

CNC turned parts in automobiles: Throttle control shaft, hydraulic valve, low pass filter shaft, pipe joint.

Mechanical

Machined parts are widely used in the mechanical industry to meet some specifications required for some manufacturing processes. Some examples of machined mechanical parts are listed below;

CNC milled mechanical parts: Gears, housings, pump handles.

CNC turned mechanical parts: Screws (rivets, bolts, nuts), motor shaft, shaft sleeve, pneumatic fittings.

Electronics

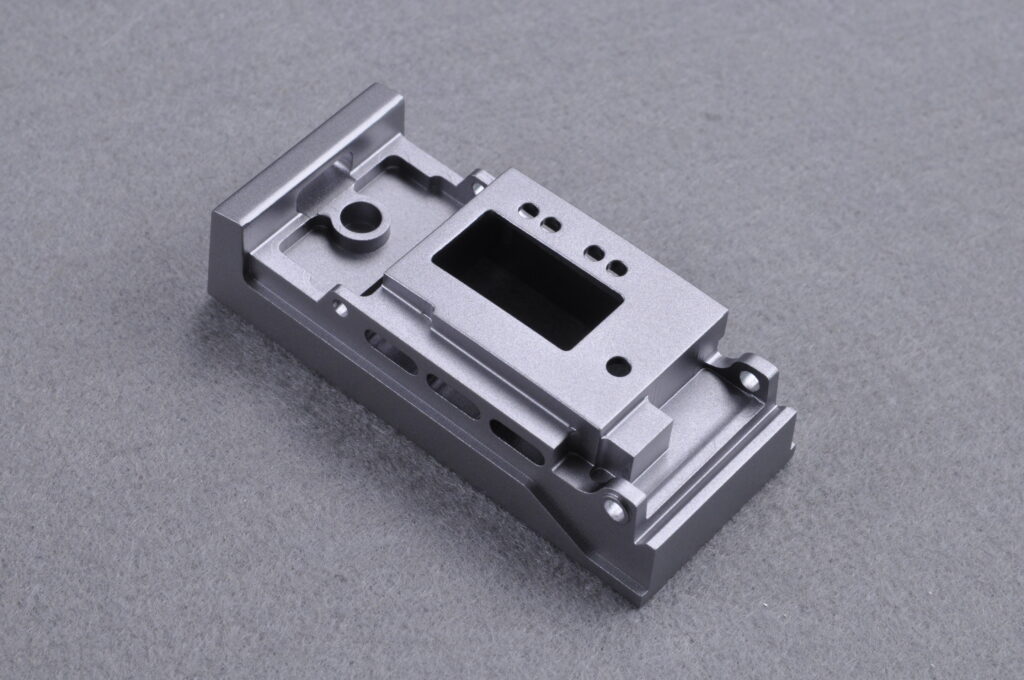

Electronics are widely used by humans worldwide for their day-to-day activities; an example is computers. The hardware parts are usually manufactured with high precision by CNC machining processes. Examples of electronic parts manufactured using the CNC machining process are highlighted below:

CNC milled electronic parts: Switches and panels, heat sinks, stiffener bars, card cages.

CNC turned electronic parts: Earphone housing, conducive pins, contact pins.

Medical

In medical technology, engineers use the CNC machining process in manufacturing equipment and tools used in the medical industry. Some examples of CNC machined parts and tools used in the medical line are listed below;

CNC milled medical parts: Implants, orthotic devices, shielded enclosures, precision surgical instruments.

CNC turned medical parts: Testing machine parts, medical mold components, R&D fixtures.

Military

CNC machining has been used for a long period in the military and defense industry. The requirement of high precision and uniformity of their weapons can only be executed perfectly by the CNC machining process. Below are some examples of CNC milled parts used in the military;

CNC milled parts in the military: Body armor, gun components, optics housing, firearm sighting.

CNC turned parts in the military: Spacers, retables, avionics, expendables.

Conclusion

CNC turning and CNC milling are both CNC machining processes. However, there is a need to be informed about the operation of both processes to know when either of the services is required. Sometimes, a CNC milled material might need a further CNC turning service to produce a part to a particular specification.