What are the types of injection molding?

Molding is the basic process of converting raw or processed materials like plastics, metals or any other pliable material into objects using a rigid frame called a mold. However there are a lot of different methods for molding materials into objects, each with its own unique industrial use. Below we have discussed a few molding processes that is used to shape a myriad of items.

Over molding

Over molding is the process in which single part is created by using two or more different material in combination, typically the first part is called as substrate which is fully or partially covered by other substance, known as the over-mold material in a manufacturing process.

Substrate

It could be anything, either metal or plastic. It is the first piece on which the molded material would be attached chemically or often mechanically interlocked material of several kinds.

Over molding material

Over molding material mostly include plastic but in pellet form (plastic mixed with additives and fillers). But this material follows some limitations. Over molding a metal part can be done with any plastic but over molding over plastic with other plastic or rubber will show some compatibility issue.

How is the process of over molding accomplished?

- In the first step the substrate material or part is placed into an injection molding tool.

- After that, the over mold material is shot into, onto or around the substrate.

- When over mold material solidifies, the two material will join together as a single part.

- It is advised that substrate and over mold material should join mechanically so that besides the chemical adherence, they will also be held physically.

Uses of over molding

Over molding is used in the making of substances included in our daily routine such as.

- Toothbrushes.

- Tool handgrips.

- Cordless drills and screwdrivers.

- Personal care products.

- Shampoo bottles and shaving razors.

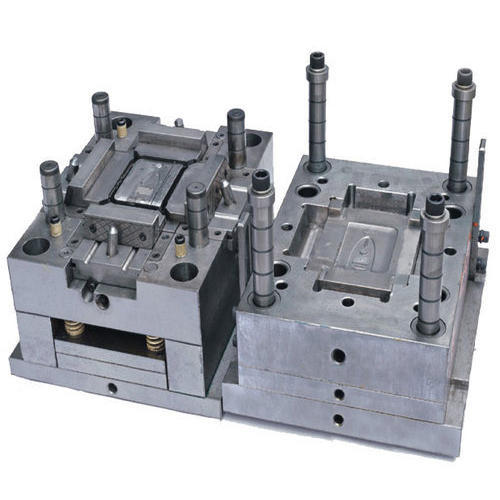

Injection molding

The process of producing parts is injection molding by injecting molten material into a mold. It can be performed with the host of material commonly metals, glasses, thermoplastic and thermosetting polymers and glasses. It is done in following way.

- The material for the component is fed into a heated bucket.

- Mixed using a helical shaped screw.

- Inject the mold cavity, cool and harden according to the shape of the cavity.

A few different types of over molding and injection molding are as follows:

- Plastic over metal

- Rubber over metal

- Plastic over plastic

- Rubber over plastic

Uses of injection molding

- Injection molding is used in the manufacturing of a variety of parts, i.e. from slightest component to entire body part of the car.

- Advances in 3D printing and technology.

- Photopolymers that usually don’t melt during injection molding of low-temperature thermoplastic.

Applications of injection molding

- In manufacturing complex plastic parts

The injection molding production process can manufacture high quality complex plastic parts. Examples include functional and housing part for automotive components, electronics and medical equipment.

- Items of daily routine

Injection molding can make many things, such as spools, packaging, bottle caps, toys, pocket combs, and so on.

- Musical instruments

It is also used in some musical instruments or making various parts of them.

- Plastic products

This process is equally prevalent in mechanical parts including gear, plastic chairs and small tables, storage containers and most other plastic product available today.

Insert molding

The process of insert molding is quite similar to over molding, but the advantage of former lies in its speed. Insert molding is a fast process because two plastic material is molded at the same time.

Nesting is the process of forming a thermoplastic material around a preformed part to create the finished part. The insert is typically metal parts that are used to enforce the mechanical properties of the plastic part.

Insert molding process

- The inserts are placed into the mold.

- Then thermoplastic is injected into the mold to form part.

- The use of die inserts eliminates the need for secondary installations and thus reduces costs

Uses of insert molded parts

Insert molded parts are used in a broad range following industries:

- Medical industries.

- Automotive

- Consumer products

- Electronic components

- Electronic housings

- Knob and dials.

- Hand-held devices.