What is Cast Urethane?

Cast Urethanes are the same as injection molding. A hard tool is a manufacture in the process of injection molding. The solid device that is made of an A-side and a B side shapes a void inside. That void is then inserted with plastics extending in material property, consistency, and durability. Dishware, Plastic cups, and toys are normally made using the procedure of injection molding for a reason they are customer items that essential to be molded on a mass scale, and injection molding is considered for the production of mass.

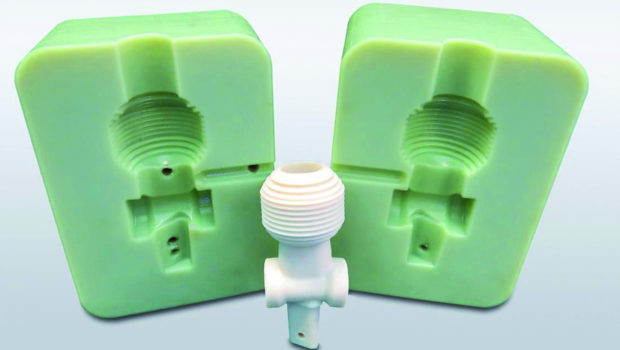

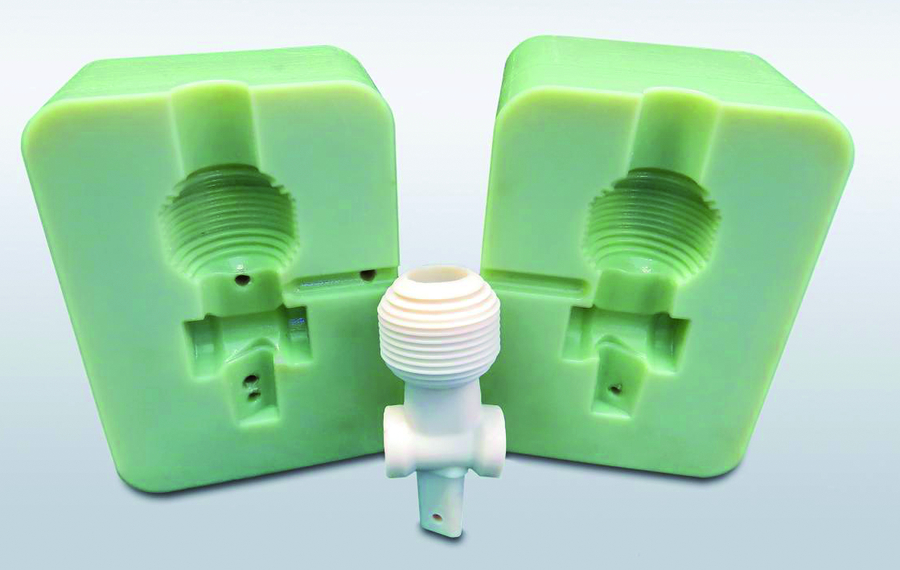

Casting urethanes is the same that polyurethanes are injected into a tool. However, the tool is a soft tool with cast urethane, usually prepared with a kind of silicone mold. The mold is shaped through a master design. For cast urethanes, Master designs can be produced with CNC machining, which is also a common process for injection molding. On the other hand, with additive manufacturing (or 3D Printing), cast urethane master designs are usually produced and the reasons for this vary.

For injection molding producing cast urethane master design is dissimilar from the phases include in making hard tooling. Hard devices are working to be exposed to heat and high pressure in the injection procedure. The consideration that goes into a hard device includes exceptional machine programming which costs a large number of dollars alone. For hard tooling, the price is well-adjusted by the mass production the tooling brings, which is the place cast urethanes start to vary. Cast urethanes are appropriate for prototyping and littler run of parts. Since the expense for soft tooling is less, down in the hundreds instead of many thousands, cast urethanes are outstanding assets for makers still testing product design, for testing market or one-off products, and customer reply to a new product.

Cast Urethanes Process

Cast urethane begins as a liquid that can be given out into a mold, post-process in stoves, and where essential, secondary machining tasks can be included. Cast thermoset urethanes have excellent physical properties over extruded or injection thermoplastics. Supplying liquid urethane into compression tools or open molds makes it conceivable to cast any setup from moderate tooling.

For an accurate silicone mold, steps include first printing a master pattern which is then enclosed in liquid silicone. It is cut into separate units after the mold cures, and then the pattern is removed. For casting the end product, the cavity designed is utilized. The void or cavity is full of material that will be processed and be detached from the tool.

Urethane Casting Materials

Advanced Formula Polymers (AFPs) will surpass your desires in short-run creation and for urethane casting. Used for item testing, alpha/beta forms, clinical preliminaries, model, and end-use parts, AFP provides an excellent choice of materials to run into your applications. Materials showing properties including MRI transparency, UL94V-0 fire rating, and also impact resistant compound protected plastics are obtainable.

Benefits of Cast Urethanes

Speed

The process of urethane casting is quicker because the silicone molds utilize to manufacture parts through this process are created very rapidly, particularly contrasted with the hard tooling utilized in injection molding. For low-volume production, it is perfect, when amounts do not explain investment in tooling of the injection mold.

If the strategy is to injection mold a huge amount of parts; however some are required instantly, at that point urethane casting is a quick technique to acquire first-run parts made before the creation tooling is prepared.

It’s splendid for testing item structure for one-off items or for testing consumer responses or business market to the new item. Urethane cast parts can take a project to its higher level with such a rapid improvement time short-run production or for end-user testing. It can give an organization a first-to-showcase advantage.

Cost

The cured and liquid poured silicone molds utilized for projecting urethane are less expensive to produce contrasted with making injection mold “hard” tooling.

To place it in context, a casting project may be many dollars, contrasted with the huge number of dollars it would be for a comparable project of injection molding.

Urethane casting, CNC machining or injection molding are the best way of producing parts that will be determined by part quantity. Urethane casting provides a great value for low-quantity parts and prototypes because the price is very less; however, the quality of the parts is superior.

Quality

The process of cast urethane can utilize a range of preparations to make parts that are hard or soft, transparent, or colored. The molds of silicone can accurately mimic manufacture textures and offer excellent surface finish detail.

Additionally, parts can be over-shaped, have post-process treatments like artistic creation, and have inserts fused into them.

With injection molding, Urethane casting makes pieces with physical properties on the same level, and the parts are physically higher to their 3D printed complements. Regardless of nonstop improvements of 3D printing, it still has structural and material integrity restrictions.