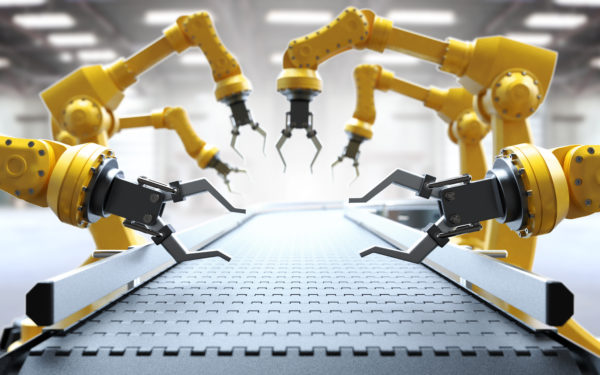

How Industrial Robotics Are Revolutionizing An Industry

How robotics has revolutionized the world can be divided into distinct phases. First is the arrival of electronic machines that are capable of performing repetitive tasks. Those were used on assembly lines of cars, as well as in the manufacturing of materials used for their production.

The second phase is all about industrial robotics, which involves machines or robots that don’t only perform simple tasks but also absorb data, enabling them to respond to new information and actively improve. These robots are predominantly present in the automotive industry, but it won’t be long before every other type of industry starts to adopt them.

At present, most automation equipment and robotic arms are used in the manufacturing industry. The electronics and automobile manufacturing industries are still the largest application markets for industrial robots, far ahead of other sectors, like food products, plastics, and metals. It comes as a surprise that many manufacturing processes are still manually done. However, artificial intelligence in robots is in a position to change that.

Significant technical limitations that industrial robots experienced in the past include dexterity and task complexity, non-visual and visual feedback, as well as flexibility and adaptability. But, how will robots with autonomous learning capabilities and better dexterity transform the industry landscape and its processes? Learn about it below.

1. Intelligent Placement

Instructions like neatly arranging or carefully handling items may seem easy for humans, but are substantial technical challenges for robots.

What’s the definition of “careful handling?” Is it to stop applying force when an object touches the tabletop? Is it moving an object to about six centimeters away from the table before letting it fall naturally? Or, is it to gradually reduce speed as one approaches the tabletop? Those are questions that need to be cleared out concerning the careful handling of an item. It’s essential to note that these instructions can have different definitions, which affect not only the speed but also the accuracy of item placement.

Arranging items neatly is more complicated. Even when ignoring the definition of “neat”, one must first pick up an object from a correct position in order to accurately place them at the desired angle and position. A robotic arm is, of course, still not as dexterous when compared to that of humans. Even the current robotic arms are still using suction cups. That said, there’s still a big room for improvement when it comes to achieving fine motor skills similar to what human joints and fingers have.

Also, humans can instantly determine the shape and angular position of the object before gripping it. Based on the cup example, the robotic arm must know whether the object is in a face-up or a face-down position, whether it has to place the cup sideways or upright, and whether obstacles or other items are blocking the way? Answering those questions will allow the robot to determine where to place the object for a more efficient use of space.

Humans constantly learn various tasks, like putting down and picking up items, from birth. That is the reason why these complicated tasks get completed instinctively. The machines, however, don’t have such experience, so they must relearn tasks.

Leveraging artificial intelligence, the robotic arm can judge depth more accurately nowadays. It also learns through training, and, thus, determines if a cup faces downwards or upwards, or if it’s in some other state.

Voxelization or object modeling has also arrived and can be extremely useful in predicting and reconstructing 3D objects. Such technology enables machines to render the shape and size of an actual object more accurately. It can also help robots to more accurately place an item in the required position.

2. Vision System

Even the most advanced industrial cameras don’t possess the human eye’s accuracy in determining distance and depth, as well as in identifying deformable objects, reflective surfaces, or transparent packaging. That explains why it’s difficult to find a 3D camera that provides accurate depth, one that can identify most packages and items. Thanks to artificial intelligence, however, this situation will soon change.

Machine vision has progressed tremendously in the past few years. It has experienced innovations, like scene understanding, semantic segmentation, and deep learning. These improve the image and depth recognition using commodity cameras. Such improvements allow manufacturers to obtain more accurate image information and to identify reflective or transparent object packaging successfully, even without expensive cameras.

3. Scalability

Deep learning doesn’t require pre-registration or the construction of 3D CAD models of each item, unlike traditional machine vision. After training, the artificial neural network can automatically identify the object based on the image.

Self-supervised or unsupervised learning will also be useful in reducing the need to tag data or features manually, allowing machines to more closely imitate human learning.

Machine learning will reduce the need for intervention from humans, and enable robots to handle new parts even without engineers having to rewrite the program. As machines gather more data throughout their operations, machine learning model accuracy will also be further enhanced.

At present, typical production lines have surrounding equipment, such as a conveyor built, a feeder, and a shaker table, to help ensure that robots can take all required components accurately. However, as robotic arms become even smarter with further developments in machine learning, the peripherals, which are four to five times more expensive than industrial robots, will no longer have to be around soon.

Also, since deep learning models use cloud technology for storage, robots can learn from each other by sharing knowledge. For instance, if one robotic arm learns how to combine two different parts overnight, a cloud update will take place, and the new model gets shared with other robots. It doesn’t only save the learning times of other machines, but also ensures consistent quality.

Final Thoughts

The most significant change that industrial robots armed with artificial intelligence bring has to do with the fact that, in the past, robotic arms could only repeatedly perform the writing process of the engineer. And, while accuracy and precision were there, these couldn’t cope with processual and environmental changes. Thanks to artificial intelligence, industrial robots can now learn how to handle wide-ranging tasks and objects on their own.

The major breakthroughs mentioned and discussed above are only a few of the developments one can expect as industrial robots will continue to revolutionize not only the manufacturing industry, but also mining, military, public safety, and health care, among others.

What do all these things mean to the manufacturing landscape, as well as to other industries? Is a major industry reshuffle going to take place? Answers to these questions should unfold in the coming years. There’s still more to come from industrial robots, and fully-automated factories are not far away. It’s only a matter of time when the highest degree of automation is achieved.