Advantages of High Quality Printed Circuit Boards

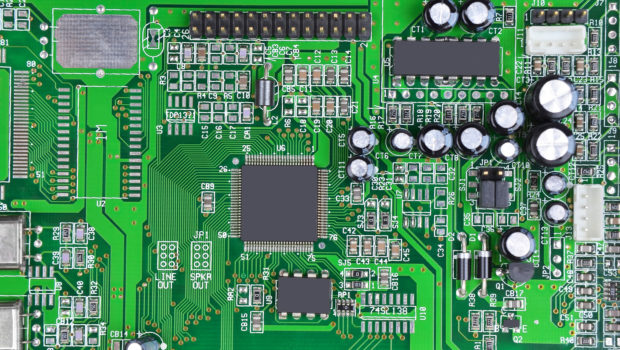

Every electronic circuit is made up of components including transistors, integrated circuits, capacitors, and resistors that are then connected together to make up simple and complicated products from doorbells to computers.

In the past, these boards are assembled by hand, which makes the process tedious and manually challenging at the same time. From trimming and cutting numerous loose wires to soldering each one, the process is slow and not to mention, is prone to errors. Checking the work and correcting any mistake is difficult too, since technicians tend to have their own way of placing and positioning the wires.

When printed circuit boards or PCBs were invented, electronic assembly became faster and more efficient. Creating hundreds of circuits for various other components became easier to do too, something that would have been next to impossible if done manually.

Types of PCB

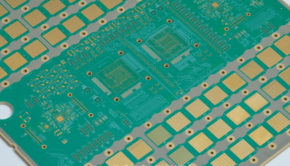

Typically, PCBs are constructed out of a board that is made up of epoxy and fiberglass. Wires are replaced with photographically printed traces. These traces are then etched chemically onto copper layers. This results in conductive lines that are not only able to connect electronics parts just like any individual wires, but are also bonded securely on the board.

There are different types of PCBs in the market today. Oftentimes, they are differentiated based on the density and spatial requirement along with the complexity of the circuitry they provide. Generally, there are three basic variants of PCBs and these are:

· Single-sided- This board has conductors etched only on a single surface of the board.

· Double-sided- Doubled-sided PCBs have conductors on the two sides of the di-electric board. The layers are also connected via PTH or plated through holes.

· Multilayer- Multilayer PCBs have conductors on three layers or more of the dielectric base. Pads or PTH are used to interconnect these layers.

Advantages of a good PCB

There is a variety of advantages from using a printed circuit board. This has made them the ideal choice for businesses that specialize in the manufacture of electronic instruments, equipment, and components anywhere in the world.

No need for bulky wires

A typical PCB has numerous electronic components despite its compact appearance. This is achieved minus the presence of hundreds of wires too. On a PCB, interconnection among components is done via copper tracks which eliminate the need for installing wires that carry current. As a result, even the most complicated interconnections will still appear less bulky when done on a PCB- which leads to products that will occupy less space.

Compact size

Most PCB components are in small sizes. PCBs offer a simple platform where electronic components are not just arranged efficiently, but are compressed neatly too, to save space. This compact nature of the board and its design means that even the most complicated electronic circuits can be created small, leading to devices and products that are relatively compact and lighter as well.

Easier diagnostics and repairs

Since there is no such thing as a perfect system, in the event that there are damages to the PCB, checking the area where the failure occurred is easy. Replacing the damaged component is easier as well. When a printed circuit board is properly designed, all the electronic components and their inherent polarities will be properly labeled on the surface. This means that installation is going to be easy to do not to mention the repair process as well. When everything is clearly labeled, being able to trace the signal paths when performing diagnostics will be a breeze. It leaves no room for second-guessing.

Saves time

Going the conventional route when installing circuit connection is just plain tedious. It takes ages to get everything connected and installed. With PCBs, assembling a circuit takes less time. Even those products that require hundreds of circuit connections can be completed at a much shorter time, which leads to faster production turnout.

Secure

Since there are no physical wires connected to and dangling from the circuit board, you get the benefit of a more secured connection. Even when you have to move the board about all the time, you won’t have to worry about one of the wires getting disconnected as everything is attached and fixed securely to the board. Thanks to solder flux, any component on the board will be prevented from going loose no matter how much you move the board or carry it around.

Prevents short circuits

Connections on the PCB are automatically done through the use of copper tracks. This eliminates the problem of loose connections. When your connections are effectively fixed and secure don the board, you won’t have to worry about short circuits, loose connections, or other related issues.

Low cost

PCBs allow for circuit connections to be done faster. Even the most complicated designs that require hundreds of interconnections to be done on the board could take much shorter span of time. This means that any manufacturer can produce them in record time, which certainly helps the production outputs, allowing them to meet customer demands more effectively.

Low electronic noise

When a PCB is properly laid out, it will produce less electronic noise. Higher electronic noise means less efficient circuit performance. Since printed circuit boards allow for a more efficient and more accurate installation, errors are significantly minimized which means that the result is a circuit with low electronic noise.

Thanks to how printed circuit board electrical components are properly organized, this results in the reduction of electrical current and path lengths passing between them. As a result, there is low electromagnetic wave pickup and radiation present. This leads to a lower crosstalk between the varied traces and components on the circuit board. Crosstalk is always a major concern where electronic circuits are involved as they are usually causes for electronic noises that are often released via flickering sound, radiation or heat.

Reliable

Overall, printed circuit boards just tend to be more reliable. With connections that are secured and fixed on the board, there is no room for connections getting loose. Since everything is marked and properly labeled, it becomes easier to trace components and parts while also paving the way for easier diagnostics in the event of the need for repairs.

The technology involved in printed circuit boards allows for thin traces and high-density connections. This leads to the manufacture of smaller, less bulky devices. Some resistors on these boards are even the size of a grain of sand so even for such a very small space, hundreds of connections can be easily packed.

If you want to learn more about PCB related articles, check out this blog: https://www.pcbonline.com/blog