Benefits of Linear Stepper Motors

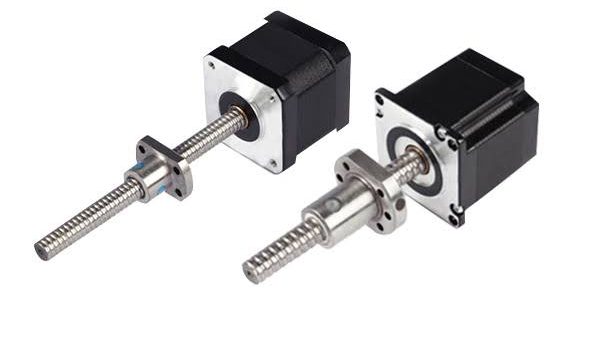

Like some of the other linear motors, the linear stepper motor is simply a variation of the famous rotary design that has been cut radially and laid out flat. While it is similar to its counterparts in terms of functions and a few basic features, the linear stepper motor runs typically as an open-loop system and is capable of providing high resolutions at an incredibly high speed and acceleration. Unlike the other linear motors that are quite popular today, the linear stepper motor comes with a hybrid design with two main parts; a base (which is also referred to as a platen) and a slider which is oftentimes referred to as a force.

What makes it different?

While we mentioned earlier that the linear stepper motor is like the rest of the other linear motors, you will find it interesting to know that it differs when it comes to the parts or components. For example, the platen which is rightly mentioned above as the main part of this motor is a passive component and is most of the time a steel plate with slots that are milled into it. The slider or forcer, on the other hand, is made up of laminations with motor windings, slotted teeth, and also a permanent magnet. The teeth of the forcer here concentrate the magnetic flux that is created when there is current in the coils. Additionally, the teeth of the forcer are also made to be staggered in relation to the platen teeth to ensure that constant attraction is maintained and that the next set of teeth comes into alignment.

The flux that exists between the platen and the slider is said to create a magnetic connection, meaning that bearings (that can either be mechanical or air bearing) are integrated into the linear motor system to ensure that the right or accurate air gap is maintained between the slider and platen. The platen tends to serve as the air bearing surface when air bearing is used instead of the mechanical bearing.

Industry uses of Linear Stepper Motors

Over the years, linear stepper motors have been used in a wide range of applications and they are still being used today. The trend of stepper motors in the last couple of years has moved towards computer control, miniaturization, cost reduction, etc. Currently, the hybrid design linear stepper motors are being used in an increasing number of applications across various industries. One can rightly say that the use of linear stepper motors has expanded in the last five years. They are currently followed in some of these applications; blood analyzers, image equipment, automated stage lighting, printing equipment, valve control, X-Y tables, inspection, and test equipment, and also integrated chip manufacturing. The technical nature of these stepper motors helps to reduce the use of a wide range of components as well as the associated costs related to assembly, inventory, and purchasing. The use and application of these stepper motors are only limited by the imagination of the designer.

Benefits Of Linear Stepper Motors

When it comes to the use of this type of stepper motors, there are a number of benefits that users stand to gain. While it is similar to a number of other motors, this stepper motor has been designed to offer more benefits and features.

- Saves cost; this has been identified to be one of the many benefits that are associated with this stepper motor. Unlike the others where you will have to either couple components together or assemble several parts, this linear stepper motor does not require any of this. All you have to do is install and begin making use of it.

- Reduced failure rate; the lack of numerous components means that the failure rate is reduced to the barest minimum. Stepper motors with a wide range of components to be assembled tend to experience an increased failure rate because of the number of components used. The lesser the number of components, the lesser the failure rate that is to be experienced.

- Depending on the type of task to be carried out, there could be no need for a linear guide. The nature and design of this stepper motor ensure that it is capable of lasting for a long period of time.

If you need more information about linear stepper motors, visit www.intellidrives.com