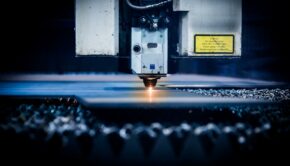

Unveiling the Art of Spindle Design Services: What You Need to Know

If you’re new to the world of CNC machines and will be opening a machine shop, there’s a lot you need to know. If you don’t learn anything else, you must be aware that the spindle is the most essential part of the CNC machine. If the spindle malfunctions for any reason, then the machine will fail to function optimally. While a CNC machine equipped with a failed spindle might continue to function, it will produce inaccurate work and waste materials in the process.

What is a spindle, you might ask? A spindle is a shaft-like component that is positioned in the center of the rotating axis of a CNC machine. The spindle is what tools are attached to for the operation of a machine, and it is the heart of the machine. The spindle is responsible for rotating the tool that cuts the material. Here is an overview of what you need to know about the art of spindle design services so you will be completely aware of what to expect.

Why Spindles Must Undergo Strategic Design

Again, the spindle is the primary component of the CNC machine, and it, therefore, must be built to last. Spindles undergo a great deal of abuse on a daily basis, and without being artfully designed, spindles would only last a fraction of the time. Some of the abuse that spindles undergo includes being dropped, being manipulated to cut various shapes on many different materials, heavy vibration, and much more.

Spindles are delicate, which means that each time one is dropped or otherwise not cared for properly, it could cause it to fail. However, the higher the quality of the parts used to construct the spindles, the more likely they are to resist failure during normal use. The higher-quality spindles are significantly more expensive and more challenging to learn to use.

Spindles are strategically made, so when they malfunction, they must undergo an extensive repair and reconstruction process. This process must be performed by a trained professional, and it’s always recommended that a spindle expert make spindle repairs and rebuilds from the spindle manufacturer. That way, OEM parts and specific expertise will ensure the repair/rebuild is optimal.

Buying the Proper Spindle

When searching for a new spindle to add to your machine shop, it’s a good idea to consider several factors, including price, type of material used to construct the spindle, and more. Common spindle materials include aluminum and metal. Aluminum spindles are appropriate for basic materials, while metal is reserved for heartier, more rigid materials.

There are four primary types of spindles: belt-driven, gear-driven, built-in motorized, and incline. Each type of spindle has its own specific set of pros and cons, and each one is suited for use with certain types of materials. Before making a final choice, it’s important to determine which kind is best for your specific needs. You don’t want to choose a spindle with inadequate torque if you’re dealing with sturdier materials, nor do you want to waste money on a pricier spindle if a less expensive one would have sufficed.

It’s also essential to choose a spindle with a greater RPM when processing certain materials because the greater the RPM, the more torque and power it has. If you’re unsure which spindle would be ideal, performing research and asking for expert assistance can help point you in the right direction.

Maintaining Your Spindles

Regardless of the quality of the spindle that you ultimately opt for, proper maintenance is necessary for longevity. Without adequate maintenance, even the most expensive and the highest quality spindle will fail prematurely. What does the maintenance of a spindle entail? Proper maintenance must involve a strategic plan to ensure several aspects of the spindle, which include:

- Lubrication – Not only do spindles require lubrication, but the lubricant must also be one the manufacturer specifically recommends. Without an adequate amount of lubricant as well as the correct type, your spindle will quickly fail. Lubrication prevents heat damage, friction, and excessive wear.

- Inspection – Inspecting your spindles on a regular basis is an important part of the maintenance process. Imperfections are typically visible before they begin to pose a problem, so regular inspections can prompt you to fix spindle problems before they begin affecting the quality of your work.

- Storage – Whenever you are taking a break from using certain spindles, they must be properly stored to prevent damage. The storage area must be free from humidity and temperature control, as harsh temperatures could result in your spindle sustaining damage. Thermal expansion, corrosion, and rust formation are just some issues that could arise if spindles aren’t kept in temperature-controlled environments.

- Protection from contaminants – Contamination is a major reason why many spindles fail. Ensuring your filters are kept clean and that you keep possible contaminants away from your spindles is a good idea.

- Clean your spindles – Another important step in the maintenance process is simple: cleaning. Cleaning your spindles regularly helps remove harmful oils and debris, which could result in damage.

As you can see, spindles are complex and critical components that must be carefully maintained for optimal performance. Spindles are artfully and strategically made because they need to have the ability to withstand certain functions. All spindles aren’t appropriate for all materials, so you must be mindful of the materials you will be processing when purchasing a spindle. Using an aluminum spindle to process inflexible material like steel isn’t a good idea. Despite the strategic manufacturing of all spindles, aluminum spindles are more suitable for softer materials like wood, plastic, and leather. Regardless of the type of spindle you’re using or the type of material you’re processing, as long as you adhere to the manufacturer’s recommendations, you should experience minimal problems with your spindles.

Cover Image by Freepik