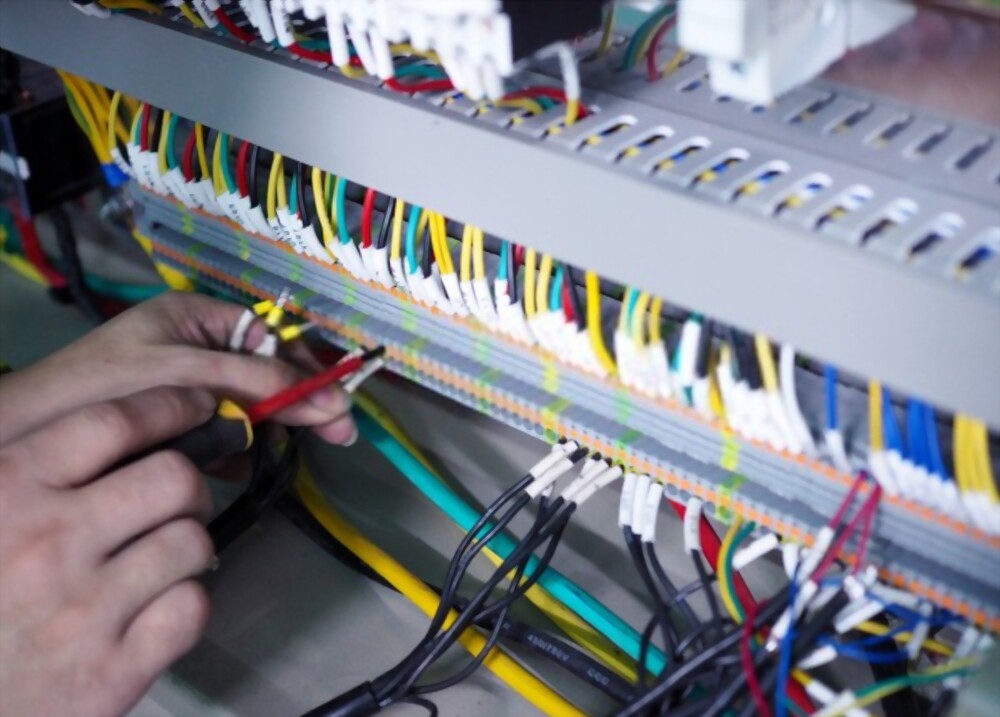

The Importance of complex industrial PLC control for your business

There are different types of industrial controls available, but PLCs are the most popular one among them. PLC means programmable logic controller, and you can use a customized PLC program to monitor your manufacturing and administrative process. With PLC industrial controls, you can manage your production line and process, and you can keep your data secure.

Apart from that, you can collect vital information from the machines used in your manufacturing unit and change their configuration according to your needs. It will not only increase the productivity of your business, but PLCs can also help you to establish a safe environment for your workers. Reducing any damages to the products at the same time.

Who was invented PLCs?

PLCs were launched by MoD icon, and it was designed to avoid rewiring and usage of additional hardware for new configuration. The popularity of PLCs was increased in a rapid speed because people were looking for such industrial controls that can save their desk space to accommodate new logic. It was 1969 when Dick Morley invented the first PLC named PLC model-084. But the first successful PLC was launched by Michael Greenberg in 1973, as PLC model-184.

Complex industrial PLC control:

Working with a complex PLC industrial control system is not an easy task because you can find all the required features including a drag-and-drop facility in your PLCs. It does not require any experience and a fresher can easily complete his or her work on a customized program. Based on the kind of products you can hire companies who can provide customizable features and design accordingly with the necessary formalities.

They can also add some changes and customized features in their PLCs and deliver a full-scale program for your business. Before you choose a PLC, you need to know the working principles of such programs. Here you can find the information regarding the working model of such industrial controls:

You will find four stages in a PLC program, such as input, program, output, and housekeeping. Through the input scan, you can scan your devices connected with your industrial controls, and the program stage will scan and execute the user created by the program logic. With the output scan, you can engage or de-energize all output devices connected to your PLC. The final stage or the housekeeping program will communicate with the programming terminals

Ladder logic is the main language used in complex PLCs, but there are some other languages that you can use. For example, you can use ladder diagram instead of ladder logic programming language because you can find different functions in your PLCs designed with Ladder Diagram, such as counters, shift registers, math operations, and timers. Apart from that, you can use the following programming languages to create a PLC for your industry controls:

- Function Block Diagram (FBD) –You can use this language where you can use data flow through re-usable function blocks. It can establish an interconnection network in your industrial controls or devices.

- Structured Text (ST) – It is a structured programming language where you can use PASCAL and can add a wide range of functions for the operators.

- Sequential Function Chart (SFC)- It is an overview of your PLCs, and you can build blocks to store your entire data with this system. Each file stored in your device will be created through a different programming language. SFC is mainly used for structuring complex PLCs.

So now, you can simplify your production line with PLCs or industrial control systems, and you can search for such industrial controls online to choose the best one.