Embellish Your Boxes with Stunning Finishing Techniques

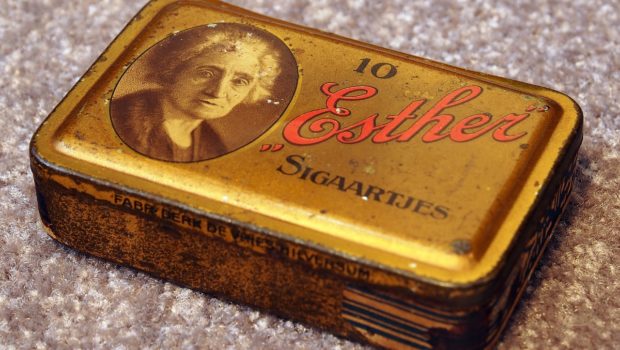

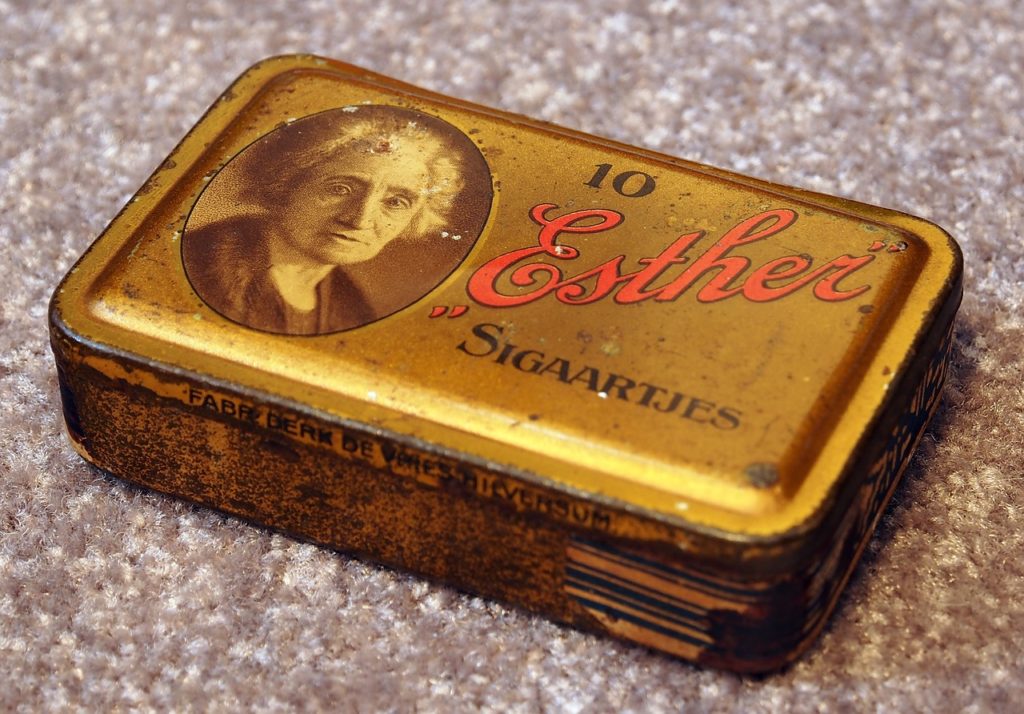

Beauty is an indescribable word. It is a feeling, sensation, thought, a mode of perception, and a lot of things. But beauty holds a specific meaning in the business as attracting customers with your product is the most challenging and exciting process. Every brand knows that their products will be sitting on the shelves in a box or some other type of packaging, and they have to design it differently in order to come under the spotlight. It might be easy for things like TV or smartphones because you know that you will be getting an iPhone when opening a box bought from Apple. However, products like scented soaps or a series of cigars need to put in more effort to become eye-catching.

In today’s topic, we will discuss various ways to enhance your product packaging appearance. One of the most important and easiest ways to do it is by furnishing your boxes’ texture, design, and shine with unique finishing styles. You can give your packages a simple look or a three-dimensional effect. We will take a look at different finishing options and how you can combine them for a gratifying experience.

Before we dive into the article, please make sure that you are buying your packaging from a trusted brand as the boxes’ material quality affects finishing. For instance, you can buy custom cigar boxes from https://impressionville.com/custom-cigar-boxes-wholesale/ as they are tried and trusted and give every sort of packaging at reasonable prices.

Embossing and Debossing

This technique exists for ages and still has not lost its touch. Embossing is a process that creates a raised image on a material with the help of a special form of dies and heat. In contrast, debossing is similar but opposite in direction. It means that it creates a pressed image in the material.

You can use them separately or combine them to create an enthralling effect. Not only that, but you can also add UV spotting or foil with both of these methods to give more detail to your artwork. These methods support various forms of printing, like single-, multi-level and sculptured modes.

Die-Cutting

It is used to give prominence to a specific word or shape on your boxes with unique cutouts. It brings the substrate underneath in work to create a contrastive effect. It uses custom-made dies to give your product an embellishing appearance.

Varnishes

If you are looking to furnish only a particular spot or the entire sheet, varnishing is your way to go. In this process, your printing is kept safe under the finishing with a glitzy texture and contrast. You can find it in various touching and visual experiences, like gloss, matte and soft touch.

You can also combine various varnishes together to provide certain areas of your boxes with the limelight. It is best to underscore your brand’s name or logo.

Foil

To give your packaging a metallic look, foil can be used in either hot or cold processes. It provides a vibrant and reflective metallic appearance to give prominence to your features or visuals. You can use standard metallic options, namely silver, rose gold, or shaded metallic with RGB colors. You must have seen how holographic foil gives different colors at different angles.

Glitter Coating

Its name is self-explanatory. This coat is created by pouring glitter particles to UV spot finishing, specifically gloss one. You can produce numerous appearances with a series of colors and using various bases and glitters.

Glitter coating is the demanded option to pull in attention and highlight your packaging details. It would be awesome to use a light-shaded background to enhance its impact.

Metallic Sheen

For a complete metallic look, you can use metallic sheen finishing for a luxurious vibe. Your custom boxes can be coated with traditional metallic and desired colors for an engaging appearance in the market.

Pearlescent Finishing

It is similar to the subsequent coating and creates a shimmering and reflective impact. It will reduce the dramatic effect that glitter causes and give a nuanced textured look. It can also be combined with different hues to have a distinctive look.

Grit & Sandpaper Coating

It gives a tactile image on the boxes for a protective layer. It would be best to be mindful that grit is a coarse technique, whereas sandpaper is relatively less rough and coarse than the standard sandpaper. It is fortunate to know that you can control the texture to give it a measured effect.

Conclusion

These finishing styles will be of no use if you are hiring the service of a remarkable printing and packaging company. The experts are well aware of the impact and use advanced technology to create a surreal experience.

These are a few of the most beautiful coatings that you need to follow the packaging industry’s latest trends.