Broaching Standoffs for Printed Circuit Board

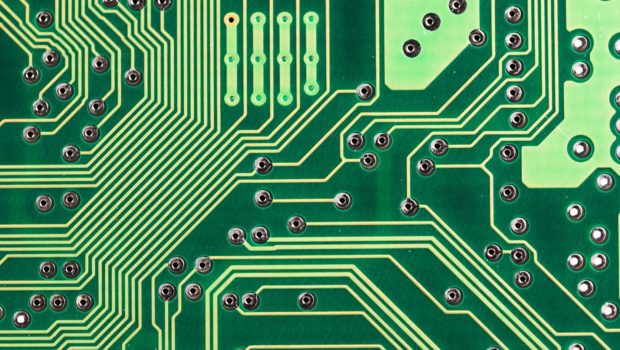

Broaching standoffs are used to install in the printed circuit board. With this, you will be able to install screws through multiple layered boards or stacked assemblies.

When talking about hardware for the applications of the printed circuit board, several designers might either use loose fasteners or broaching fasteners from bisco industries.

Even though both offer necessary functionality, each of them comes with potential risk, which might have an impact on the production process, the board’s integrity, and also disassembly if needed.

What’s A Broaching Standoff?

Loose hardware that is specified for boards come with spacers, screws, and nuts that generally require secondary installation-associated operations that are performed manually.

- The secondary operations might take up a lot of time. That is primarily because of the painstaking work required for aligning all parts.

- When the installation is complete, another step needs to be taken to make sure that no loose parts are missing in the assembly as the errant parts might lead to end-product failure.

- Another issue is disassembly, as loose hardware has to be contained.

Broaching fasteners like nuts and spacers can eliminate the problem of loose hardware. However, the improper installation might lead to many issues.

Bisco Industries standoffs offer strong reusable threads in a spacer format in non-ductile materials like a printed circuit board. It features an axially knurled shank; its serrations have been created to cut the panel material as it has been installed.

This results in an interference fit that offers good pull-out performance and torque-to-turn resistance. It is simple to install. You just have to prepare a specified hole and use a flat punch and right anvil.

Thereafter, you will have to apply a parallel squeezing force for pressing the part into the hole. While installing the PCB, broaching standoffs are best just for the non-plated holes.

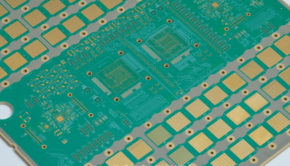

Broaching standoffs are available for thru-hole sizes and metric thread in electro tin-plated steel. It is ideal for installing panels that have a maximum hardness of 60HRB.

How to Find the Best Standoffs for PCB Assemblies?

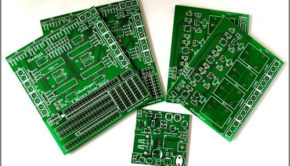

Integrating PCB into an assembly is a customized job. Every application has a different board location.

- Some boards might be spaced or stacked, and others have to be removed and then re-attached. All these can complicate board attachment whether you specify board-to-board, component-to-board, or board-to-chassis.

- There might be a wide range of hardware in the fastening toolbox, but not all of them are practical, particularly if you are working with sensitive electronics.

Broaching standoffs can simplify the production process. This helps in increasing product quality and reduces the overall cost.

- Eliminate Loose Hardware Issue: The best way to get rid of the loose hardware problem is to get broaching standoffs. These are installed permanently in all types of PC boards with the fewest parts available.

There are various types of them in the market, and each comes with its own function. Nevertheless, all types can be installed easily and quickly.

- Easy to Install: Many PCB mounting fasteners use the same kind of soldering processes that mount other electronic components. For instance, with surface mount fastening, the hardware is positioned when the board is being processed.

Traditional surface mounting equipment then installs along with the other electronic components. Factors like board misalignment and cracking are less likely to happen as the hardware can be installed automatically with the same robotic equipment that is used for the electronic components of the board.

The process isn’t intrusive to the board and doesn’t expose it to crackling. It will let you state the close-to-edge installation.

How to Install Broaching Standoff?

For installing a broaching standoff, squeeze it with a flat anvil and punch. You need sufficient force so that the tips to project the knurl teeth that are embedded to where the knurl contact’s inside the shoulder contacts the board.

As soon as the fastener seats itself in the right position, the shank will expand outward for completing the installation.

- Grounding standoff can be installed on aluminum or steel chassis to ground PC boards.

- Now, place the barrel end into the drilled and punched around a mounting hole in the chassis.

- Thereafter, you will have to apply squeeze force till the head is embedded and is flush with the top.

When it comes to nuts, standard standoffs, and one-piece board-mount assemblies,

- You will have to place the fastener in its anvil hole and then place the mounting hole in a board over the shank of a fastener.

- Now, you will have to exert squeezing force until the shoulder of the fastener comes in contact with the board.

- Make sure you are using a punch flaring tool along with a recessed anvil to flare-mount standoffs.

- Now, you will have to squeeze force until the fastener’s shoulder comes in contact with the board.

- When the fastener seats itself in the right position, the punch tool will flare the extended portion of the shank outward for completing the installation process.

For Surface Mount Fasteners, the pick-and-place machine will pick up the part without any patch.

- The fastener that is supplied in the reel and tape comes with two small pins pointing downward.

- This should be further off from the pneumatic finger.

- The fastener’s flat portion will face it. The two pins serve as small pilots to offer stability and location accuracy when you are placing it.

- The rectangular hole of the fastener will reduce the mass that will promote faster heating.

- It will lower the potential for the surrounding component on the board for overheating.

The plastic cap and the screw thread are supplied separately. Hence, the retainer can be placed on the board and then run through the oven. Following the re-flow, the thread and cap snap onto the retainer, which completes the assembly.

Final Words

Different types of fasteners are available for board-related applications. Stainless self-expanding standoffs are best for boards that come with plated thru-holes. It incorporates a self-expanding shaft that ascertains a positive contact with the hole.

This is also going to eliminate all risk of shaving the plating out of the hole.