Can Software Dictate Photon’s Directions?

Researchers at Stanford University say yes.

As copper wires have clear disadvantages from capped bandwidth capacity to large energy consumption and the need for transistor replacement becomes more pressing, engineers are looking into photonic circuits and fiber optics instead.

“Light can carry more data than a wire, and it takes less energy to transmit photons than electrons,” says Professor Jelena Vuckovic, lead photonics researcher and electrical engineer at Stanford. A few years ago, she studied the energy consumption of copper wires and found that up to 80 percent of a computer’s microprocessor power is consumed by sending data over the wires, or interconnects. Optical transport, on the other hand, uses far less energy and can carry 20 times the amount of data than copper can.

But photons relay information differently than electrons.

Photonic-based technology relies on frequency-dependent transmissions, and two aspects are critical: wavelength-division multiplexing (WDM) and vertical-incidence coupling. WDM is basically the process of creating virtual fibers within a single optical fiber — it breaks up white light into different wavelength “strands”, on which different types of data can be transmitted through one fiber without interference. The coupling mechanism makes sure light is guided into the optical connect and stays there, in the first place.

Both of these requirements make optical interconnects complicated to design, impractical to say the least. Stanford engineers note that conventional brute force approach to optical design typically involves a repetitive process of fine-tuning parameters utilizing components such as waveguide directional coupler, multimode interference coupler, distributed Bragg reflectors, micro-ring resonators, adiabatic tapers, and grating couplers. The process is extremely tedious and the design space small, making production nearly impossible.

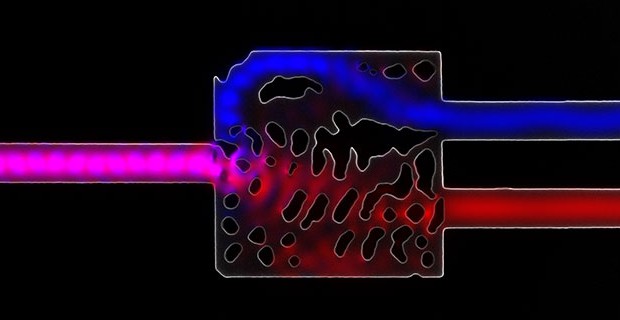

To save scientists painstaking headaches, the engineering team designed a silicon prism that takes care of both the demultiplexing and coupling problem, automating a process that cannot be replicated manually for photonic applications — through the use of software.

Software-enabled optical design

Basically, Stanford engineers are letting nature do the work.

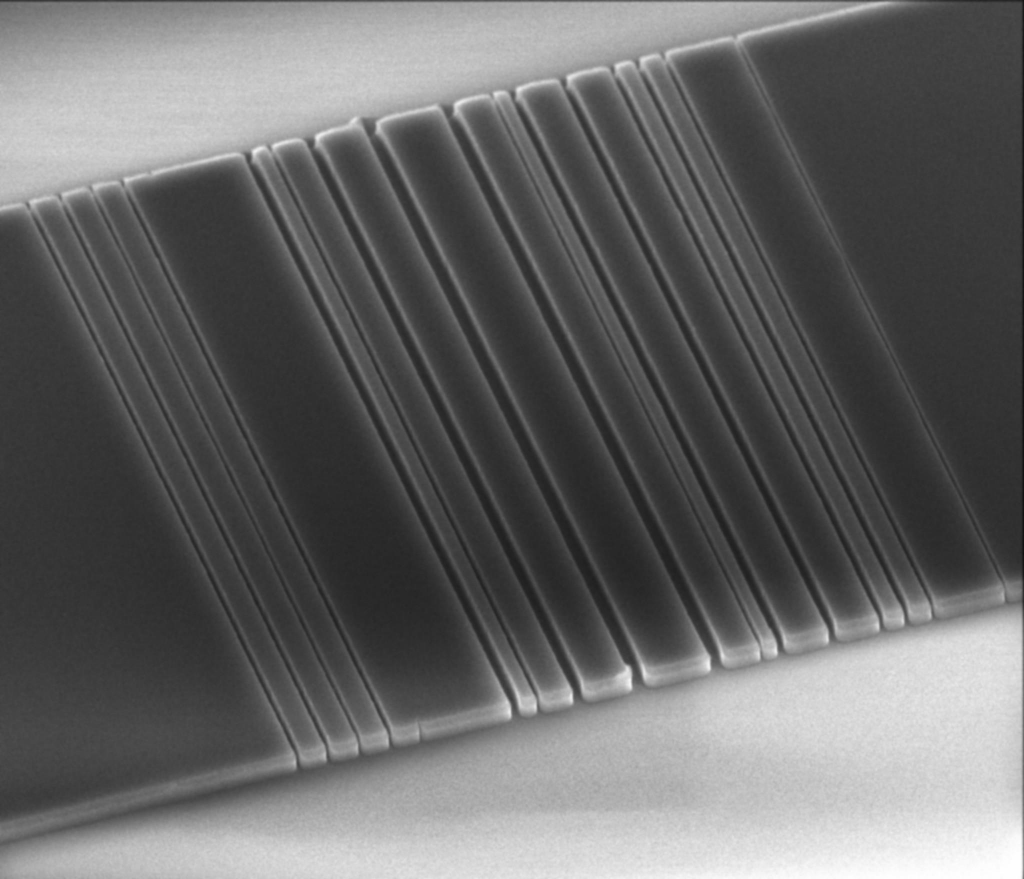

Taking advantage of the fact that light travels at different speeds in different mediums, they constructed an algorithm that takes a simple slab of silicon and etches away at its surface, according to software specifications and tiny adjustments based on convex optimization, to form unique barcode patterns that will give the exact desired output of light wanted. Particularly, the user sets the device area, input and output frequency modes, and a few other ratios, and after about 15 minutes, the computer algorithm calculates the optimized etching pattern for the silicon prism.

As the researchers describe, the resulting shape looked unusual, but it works better than anything they’ve witnessed. “For many years, nanophotonics researchers made structures using simple geometries and regular shapes,” says Professors Vuckovic. “The structures you see produced by this algorithm are nothing like what anyone has done before.”

The software-designed structure that routes light beams to different outputs based not on their color but on their mode. (image credit: Alexander Piggott)

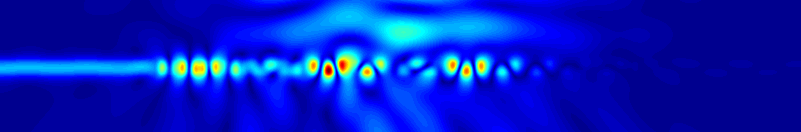

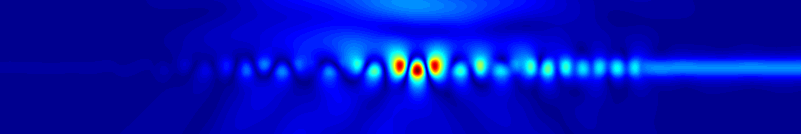

The team tested their etched device, fabricated in Silicon-on-Insulator (SOI) of less than 4 μm thick, focusing a Gaussian beam at the frequency-splitting grating and measured the results.

At wavelengths less than 1320 nm, light goes to the left:

Light more than 1540 nm couples to the right:

They’ve demonstrated the basic functionality of their device to split and couple light, and it is entirely designed by software.

One giant leap for light-based technologies

Based on the Stanford team’s success in designing the silicon prism, they’ve concluded that algorithmic solutions can indeed be tailored to meet other design requirements as well, beyond interconnects. Following their first experiment, the engineers have also successfully designed a mode-based light router which splits light beam according to color-independent modes. This is an effective way to create more “virtual fibers”, increasing design possibilities for optical communication.

Regarding commercial production, their manufacturing processes are not nearly as precise as those at commercial fabrication plants, the researchers says. The team states by vastly opening up the parameter space for nanophotonic devices, inverse-design has broad implications for the future design of novel and compact nanophotonic components with full three-dimensional freedom. And, as they commented, the fact that we could build devices this robust on our equipment tells us that this technology will be easy to mass-produce at state-of-the-art facilities.

We should note that the automation of large-scale circuit design is a driving step that makes today’s electronic possible. By automating the designing of optical interconnects through software algorithms, Stanford engineers have brought photonic technologies one step closer to reality.

Paper cited: Inverse design and implementation of a wavelength demultiplexing grating coupler – Nature

![The ePrivacy Regulation and Its Impacts [Infographic]](https://technofaq.org/wp-content/uploads/2019/06/cropped-150x150.jpg)