The future of industrial automation

Introduction

The worldwide recession has had a remarkable impact on the growth of various businesses. Industrial automation is one of the sectors that has grown and is growing towards heights of eminence. To achieve progressive automation in the current business environment, it is paramount for companies to adapt, invent as well as utilize the available resources so as to generate growth and productivity. This article is a summary of the direction the automation industry is taking in the future.

The rear-view mirror

Innovation and technology are the core catalyst that will spur reestablishment of growth in the industrial automation. According to the author of the article, there will be no technology inventions to create the next Apple, Microsoft or Cisco. Future trends cannot be forecasted by only extending the activities that have been undertaken in the past. This is likened to a driver who uses only the rear-view mirror. Just like driving, the future of industrial automation involves a combination of several aspects to make it worthwhile. The industry does not induce to cheaper and smaller DCSs, PLCs, supervisory control or the data acquisition systems. These functions are to be entrenched in the software and hardware. The desired future will be achieved from new, totally different and advanced directions.

New technology directions

Concerning technology related inflection points, the industrial automation and control will create massive growth. For instance, generation of nanotech sensors such as low-cost sensors, low-power, and tiny, MEMS, nanotechnology as well as nanoscale assembly systems that can and will measure anything. Also, the machine to machine (M2M) networking and the pervasive internet.

The complex adaptive systems, as well as multi-processing, will replace the real-time systems. Apparently, the nanotech, complex adaptive systems, and most wireless systems will be common in the future. The core new software applications will have taken another channel of distributed peer-to-peer networks and the wireless sensors. The small operating systems in the wireless sensor nodes as well as the software that gives way to the nodes for the purpose of communicating with others as a bigger complex adaptive system. The wave foreseen in the future is as mentioned above.

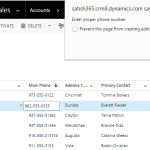

The fully-automated factory

The rebuilding of automated processes and factories is expensive, especially with consideration of modification and changing the designs. For this reason, they must be highly flexible and configurable. However, for configuration of a complete process or production line there must be direct access to the control elements such as valves, motors, switches as well as drives. The remote-controlled automation that has been a vision for the past many years is already in existence. There is the availability of online orders, electronic transactions that have the capacity to negotiate batch sizes, prices, color, and size. The complex machines and the intelligent robots effortlessly and swiftly fabricate diverse customized products that are highly demanded.

In the maintenance applications and manufacturing settings, the remote-controlled automation is already making headway. In the past, people underestimated the power of communication especially the thought of super-robots operating solely. However, in the current world this is networked intelligence that is well developed and the availability is not limited.

There is the availability of a communications support for the automated processes. These include several sensors, swift networks, quality flexible interfaces and diagnostic software. All of them have a high degree of pervasive access and reliability to error- correction systems, hierarchical diagnosis and the centralized operations.

The winning differences

The automation companies have no choice as they must come up with diverse ways to achieve global expansiveness. They must minimize control of the central corporate cultures as well as maximize receptiveness to the needs of the local consumers.

Pingback: STARTUP-BOOST YOUR SMART HOMES IQ | Design Swan